We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

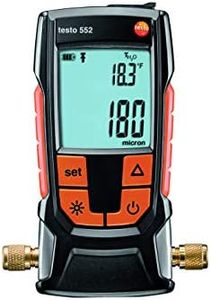

10 Best Micron Gauge Hvac

From leading brands and best sellers available on the web.Buying Guide for the Best Micron Gauge Hvac

When choosing a micron gauge for HVAC work, you're looking for a tool that accurately measures the deep vacuum levels needed for evacuating and servicing air conditioning and refrigeration systems. The goal is to ensure there are no leaks or moisture in the system before recharging it with refrigerant. Picking the right micron gauge ensures reliability, precision, and ease of use, making your work both safer and more effective. When shopping, focus on the essential specifications that impact accuracy, usability, and compatibility with your typical HVAC tasks.Measurement RangeThe measurement range tells you the span of vacuum levels the micron gauge can detect, usually given in microns (where lower numbers indicate a deeper vacuum). This is crucial because HVAC systems require evacuation down to at least 500 microns to remove moisture and air. Some gauges only measure down to 1,000 microns, while more sensitive ones go below 100. For most HVAC use, a gauge that measures from atmospheric pressure (around 760,000 microns) down to 10 microns covers all needs. If you do more precise or specialized work, you'll want a gauge that can measure lower micron levels, but for general residential and light commercial work, a range down to 10 or 20 microns is sufficient.

AccuracyAccuracy reflects how close the gauge's reading is to the actual vacuum level. It's important because even a small error can mean you don't evacuate the system enough, risking moisture or leaks. Gages often state accuracy as a percentage of reading or as a fixed micron value (for example, ±5% or ±10 microns). For most work, an accuracy of ±5–10% is acceptable; if you do high-precision work, seek better accuracy. Choose based on how critical exact vacuum readings are for your HVAC tasks.

Sensor TypeThe sensor detects the vacuum and can be a thermistor, thermocouple, or Pirani type. These affect speed, durability, and sensitivity. Thermistors are common and reliable for general HVAC use, while thermocouples may respond faster. For typical HVAC work, standard sensor types suffice unless you're operating in very harsh environments or need particularly fast measurement updates.

Display TypeDisplay type refers to how the vacuum level is shown—either digital or analog. Digital displays give clear, precise readings and are preferred for accuracy and ease of reading in different lighting. Analog gauges may be harder to read but can be very robust. If you want simplicity and quick readings, digital is best. Consider analog only if you prioritize ruggedness.

Durability and PortabilityDurability covers how well the gauge stands up to drops, dust, and moisture in job site conditions, while portability refers to weight and size. Well-sealed, rugged cases and protective covers make the gauge last longer in tough environments. Lighter, more compact gauges are easier to carry and use in tight spaces. If you work in varying or harsh settings, choose a model built for those conditions. If your work is mostly indoors or at a bench, standard durability may be fine.

Ease of CalibrationOver time, micron gauges need recalibrating to stay accurate. Some are user-calibratable, while others require factory servicing. Easy calibration is important if you use the gauge frequently or depend on high accuracy, as it reduces downtime and maintenance costs.

Connection TypeConnection type is about how the gauge attaches to the HVAC system, such as with standard flare fittings or hose connections. A good fit ensures accurate readings and prevents leaks. Check to make sure the gauge’s fittings match your common hoses and service ports. If you often work with different systems, look for versatility in connections.

Battery LifeMost digital micron gauges operate on batteries. Longer battery life means less frequent changes and fewer interruptions on the job. Look for quantified expectations—do you want a gauge that lasts days or weeks on a set of batteries? If you often work long hours or in remote areas, longer battery life is a bigger plus.