We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

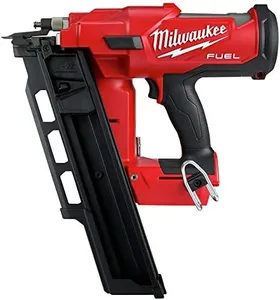

10 Best Nail Guns

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

#1

Winner

Buying Guide for the Best Nail Guns

Choosing the right nail gun can make woodworking, construction, or DIY projects faster and easier. Since there are several types of nail guns, it's important to understand which features matter most for your intended use. Think about the kinds of materials you'll be fastening, the type of projects you'll undertake, and how often you'll use the tool. With a basic understanding of the key specifications, you'll be able to pick a nail gun that is both safe and efficient for your needs.Type of Nail GunThis refers to the specific kind of nail gun, such as framing, finishing, brad, roofing, or flooring nailers. The type determines what jobs it is designed for—framing nailers are best for heavy-duty construction, finishing and brad nailers suit delicate trim or furniture, and roofing nailers are specialized for shingles. Understanding your project needs helps you pick the type that fits; for general carpentry, a framing or finishing nailer is often more appropriate, while for small crafts, a brad nailer works best.

Power SourceNail guns may be powered by compressed air (pneumatic), batteries (cordless electric), or fuel cartridges (gas-powered). Pneumatic nail guns are often lighter and deliver consistent power, making them great for long, repetitive tasks, but they do require an air compressor. Cordless electric nailers are portable and convenient without hoses, ideal for jobs where freedom of movement matters, though they may require battery changes and can be heavier. Gas-powered models are suitable for heavy-duty and outdoor tasks where both power and portability are needed. Matching the power source to your work environment and mobility needs will help ensure both comfort and efficiency.

Nail Length and Gauge CompatibilityThis spec tells you what size and thickness of nails the gun can shoot. Length matters because longer nails give stronger holds, important for structural work, while shorter nails are better for thin materials or decorative projects. Gauge reflects nail thickness; lower gauge means thicker, stronger nails for heavy jobs, higher gauge is for more delicate work. Check that the nail gun covers the sizes you need for your projects and avoid buying a model that limits your options either by too thick or thin.

Magazine Capacity and Loading StyleMagazine capacity is the number of nails the tool can hold before needing to reload. Higher capacities are helpful for big or repetitive tasks so you don't have to reload often. Loading style refers to how nails are loaded—some are straight magazines, others are coil. Straight magazines are common and easy to reload, while coil magazines carry more nails, useful for roofing or siding. Consider both the type of work and how often you want to reload when picking the right capacity and loading style.

Firing ModesNail guns can have different firing modes like sequential, bump (contact), or single-shot. Sequential firing requires a series of steps (pressing tip, then trigger) for each nail, making it safer and more controlled, especially for beginners. Bump firing lets you hold the trigger and simply bump the nose of the gun for rapid firing, suited for fast-paced work but with greater risk if not careful. Some models let you switch between modes. Consider your experience, safety comfort, and speed needs when deciding which firing mode or combination matches your style.

Weight and ErgonomicsWeight and grip shape affect how comfortable a nail gun is, especially for extended use or overhead work. Lighter models reduce fatigue and are easier to maneuver, good for long sessions or delicate angles. Ergonomic handles with good grip help prevent slipping and make the tool easier to control. Think about the typical length and style of your tasks—bigger, heavier models can be more stable for tough jobs, but may be tiring if used a lot or in awkward positions.

Depth AdjustmentDepth adjustment lets you control how far the nail is driven into the material. This feature helps prevent over-driving (nails sink too deep) or under-driving (nails stick out), which is important for getting a clean finish and avoiding material damage. Some models have tool-free depth adjustment, making it easy to switch settings on the fly. If you work with different materials and need flexibility, having depth adjustment will save time and improve results.