We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Parallel Bar Clamps

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Parallel Bar Clamps

Choosing the right parallel bar clamp is all about understanding your woodworking or crafting needs, the size and type of projects you commonly tackle, and how much stability and clamping pressure you'll require. Parallel bar clamps are great for ensuring pieces stay aligned and square while glue sets or during assembly. Your choice will be guided by the typical sizes you work with, the materials involved, and how user-friendly the clamp is for your application.Clamp LengthClamp length refers to how far the jaws of the clamp can open, which is the maximum width of the project it can hold. This is important because you need a clamp long enough to span the material you are securing. Common sizes range from about 12 inches up to 50 inches or even longer. For small projects or cabinetry, shorter clamps may be sufficient, while larger clamps are better for wide table tops or doors. Consider the projects you most often work on, and select clamp lengths that accommodate your largest typical workpiece—often, having multiple sizes can be especially practical.

Clamping PressureClamping pressure is how tightly the clamp can squeeze your materials together, usually measured in pounds. This is essential because too little pressure might not hold joints together, while too much can actually damage delicate materials. Lighter duty clamps are fine for crafts or lightweight gluing, while heavier duty clamps are better for strong hardwood joints or large panel glue-ups. Think about the force needed to keep your projects secure without crushing or bending them, and pick a clamp with an appropriate range of pressure for your most common materials.

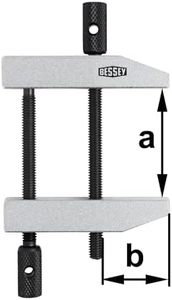

Jaw ParallelismJaw parallelism describes how flat and evenly the clamp jaws meet each other. Parallel jaws help keep your workpieces aligned and prevent them from bowing or shifting out of position during clamping. High-quality clamps have jaws that stay perfectly in line across their length. For tasks like edge-gluing boards for panels or assembling frames, parallel jaws ensure better results. If you often need precise, square assemblies, prioritize clamps known for their true parallel jaws.

Jaw Width and MaterialJaw width is the size of the surface that contacts your materials, and jaw material can range from plastic to steel with protective pads. Wider jaws distribute pressure more evenly and reduce the risk of leaving marks on your project. If you work with softer woods or delicate finishes, look for clamps with wider jaws and non-marring pads. For thick hardwoods or rugged tasks, metal jaws may be suitable, but protective covers are a plus if you want to prevent surface damage.

Bar ConstructionThe bar is the long, straight portion of the clamp, and it’s typically made from steel or aluminum. The sturdiness and rigidity of the bar determine whether it will flex or resist twisting under pressure. Lighter bars are easier to handle but may bend with heavy use, while heavier, more rigid bars support large or high-pressure projects. Your choice should be guided by the heaviest or widest workpieces you work with regularly; stiffer bars deliver more consistent results when working on big assemblies.

Ease of AdjustmentEase of adjustment involves how simple it is to open, close, and tighten the clamp, often controlled by a handle or quick-release mechanism. This matters because smooth, fast adjustments make setting up and changing clamp positions easier, especially during busy assembly work. If you prefer efficiency and often reposition clamps mid-project, look for designs with quick-release levers or comfortable, large handles.

WeightThe weight of the clamp can affect how easy it is to position and maneuver, especially if you need to use several at once. Lighter clamps are more user-friendly for overhead work or when moving between workstations, while heavier clamps might offer more stability. Consider your physical workspace and how often you have to move your clamps around. If portability and ease of handling are priorities, go with lighter options, but always balance that with the need for rigidity.