We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

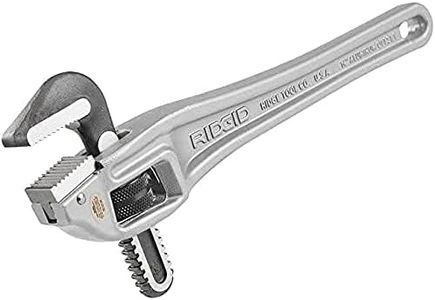

10 Best Pipe Wrenches

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Pipe Wrenches

Choosing the right pipe wrench can make your plumbing or DIY project much easier and more effective. Pipe wrenches come in different sizes, designs, and materials, each suited for specific tasks and user needs. Before buying, consider what kind of pipes you'll be working on, how often you'll use the tool, and where (tight spots or open spaces). Understanding the main specifications will help you select a wrench that feels comfortable, performs well, and lasts long.Length (Size)The length of a pipe wrench generally ranges from about 6 to 48 inches. The length determines the leverage you can get: longer wrenches can grip larger pipes and provide more torque, making it easier to tighten or loosen stubborn fittings. However, they're also heavier and harder to use in tight spaces. Smaller wrenches are lighter and more compact, perfect for small-diameter pipes or working in confined areas. Think about the size of pipes you'll most often work on — for general household plumbing, a medium-sized (10-18 inch) wrench is a good choice; for industrial or heavy-duty jobs, look at longer wrenches.

Jaw CapacityJaw capacity is the maximum diameter of pipe that the wrench can securely grip. This is important because you'll need a wrench that can accommodate the pipes typical in your work or home. Jaw capacity usually increases with the overall length of the wrench, but it's always good to check since designs can vary. For most home plumbing tasks, a jaw opening of 2 to 3 inches is often enough. If you know you'll encounter larger pipes, adjust your choice accordingly.

Handle MaterialHandles are commonly made from steel, aluminum, or even composite materials. Steel handles are strong and durable, making them ideal for heavy-duty tasks, but tend to be heavier. Aluminum handles are much lighter, reducing strain during prolonged use, but might not be as tough under the highest loads. Composite handles offer good grip and comfort but may not be as durable as metal. If you'll use the wrench frequently or for longer periods, a lighter handle could be more comfortable; for maximum strength, steel is the classic choice.

Jaw Material and Teeth QualityThe jaw, especially the teeth, are what actually grip the pipe. Hardened steel jaws with sharp, well-cut teeth provide the best grip and wear-resistance. Worn or soft teeth can slip and damage both the wrench and the pipe. For users tackling tough or old pipes, prioritize a wrench with hardened, replaceable jaws. For lighter or infrequent work, standard jaws may be sufficient, but always inspect for sharp, well-defined teeth.

AdjustabilityPipe wrenches use a knurled nut or screw to adjust the jaw opening. Easy and smooth adjustment is crucial, especially if you need to change jaw width quickly. Some higher-quality wrenches adjust more smoothly and hold adjustments better, which can save time and frustration. If you'll be working on a variety of pipe sizes, prioritize wrenches known for quick and stable jaw adjustment.

WeightThe weight of the wrench affects how easy it is to handle and use, especially in overhead or awkward positions. Heavier wrenches are often more durable and better for very large pipes, but can cause fatigue. Lighter wrenches are easier to maneuver and carry, making them better for mobile or repetitive jobs. Consider how much weight you’re comfortable lifting and how long you’ll be using the wrench at a time.

Type (Straight, Offset, End, Compound, Strap)There are several types of pipe wrenches. The most common is the straight pipe wrench, suited for general use. Offset wrenches have angled jaws for reaching pipes in tight or awkward places. End pipe wrenches have jaws set at a specific angle for work close to walls. Compound and strap wrenches are for specialty needs, such as extremely tight spaces or delicate fittings. Match the wrench type to the typical situations you encounter: straight for general jobs, offset or end for hard-to-reach places, and specialty types for unique challenges.