We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Router Table Fences

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Router Table Fences

Choosing the right router table fence is an important decision for anyone working with woodworking routers. The fence plays a key role in ensuring accuracy, safety, and ease of use as you make repeated or straight cuts along your router table. Understanding the main features and what they mean for your style of work will help you pick a fence that enhances your results and fits your woodworking needs. Consider where, how often, and with what types of projects you’ll be using your router, and let those needs guide you as you decide between the options.MaterialThe material of the fence affects its durability, weight, and stability. Common materials include aluminum, phenolic, and MDF (medium-density fiberboard). Aluminum fences are lightweight, durable, and resist warping, making them great for frequent or heavy-duty use. Phenolic fences are very stable and resist moisture, so they're a solid choice if you need something long-lasting and robust. MDF is affordable and flat, but less durable if it gets wet or knocked around. If you need something stable for heavy use or wet environments, pick phenolic or aluminum over MDF.

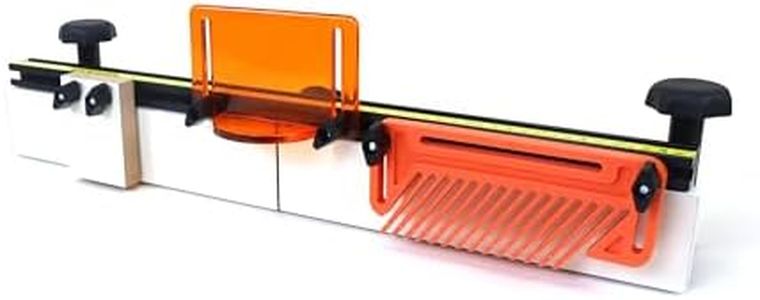

AdjustabilityAdjustability refers to how you can move and set the fence for different kinds of router jobs. The more adjustable a fence is, the easier it is to dial in precise measurements, adjust the offset, or remove the fence for freehand work. Some fences have micro-adjustment features for fine tuning, while others offer simple slide or lock adjustments. If your projects require precision and versatility, look for fences with easy-to-use micro adjustments. If you tend to make straightforward cuts, basic locking adjustment may suffice.

Face Length and HeightThe length and height of the fence face will determine how well it supports your workpieces. A longer fence offers better guidance for longer boards, reducing the risk of errors. A taller fence supports larger or vertical pieces, like raised panel doors. If you usually work with large or tall stock, prioritize a fence with greater height and length. For smaller projects, a standard fence size may be all you need.

Dust Collection CapabilityA good router table fence should offer some form of dust collection port or attachment, helping keep your workspace clean and improving visibility and air quality. Dust collection ports come in different sizes and designs to fit shop vacuums or dust collection systems. If you work indoors or care about cleanliness, choose a fence with a built-in dust port that's compatible with your dust collection system.

Split vs. One-Piece DesignFences come in split and one-piece designs. Split fences have two adjustable faces, which allow you to offset the infeed and outfeed sides, useful for jointing or working with bits that remove material along the fence. One-piece fences are simpler and work well for most standard routing tasks. If you plan to do jointing or specialized routing that requires removing material, a split fence is worth considering. Otherwise, a solid one-piece design is easier to set up and maintain.

T-Slots or Accessory TracksT-slots or accessory tracks allow you to attach featherboards, stops, or other accessories to the fence, improving safety and versatility. These can be handy for repetitive or precision tasks where added support is helpful. If you think you'll want to use accessories to make your work easier and safer, choose a fence with these slots built in. Otherwise, a basic fence may be sufficient.