We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Solder For Electronics

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Solder For Electronics

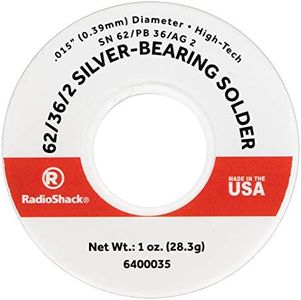

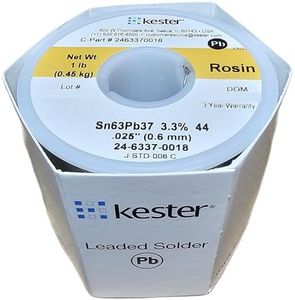

When choosing solder for electronics, it's important to consider how the type of solder affects the quality and reliability of your circuit assemblies. The right solder can make your work cleaner, easier, and more durable, while the wrong choice can lead to weak joints or even damage your electronics. Understanding the main specifications will help you pick solder that fits both your experience level and your typical projects.Alloy CompositionAlloy composition refers to the metals mixed together to make the solder. The most common types for electronics are lead-based (often 60/40 or 63/37 tin to lead ratios) and lead-free (usually tin mixed with small amounts of silver and copper). Lead-based solder is easier to work with due to its lower melting point and excellent flow, but it's less environmentally friendly and is restricted in some industries due to safety regulations. Lead-free solder is safer for health and the environment but needs a slightly higher temperature to melt and can be a little trickier to use. If you’re just learning or working in a personal setting, either can work, but check your project requirements and consider regulations if you’re making products for others.

Wire DiameterWire diameter determines how thick the solder strand is. Thinner solder (like 0.4mm to 0.6mm) gives better control for small and detailed work, such as surface-mount components or fine-pitch parts, as you can apply small amounts with precision. Medium-thickness wires (around 0.7mm to 1mm) are good all-rounders for most hobbyist and standard circuit work. Thicker wires (above 1mm) are suited to larger joints, like those found in power connections or big components, but can easily apply too much solder to small jobs. Choose the thickness based on the size of the components and how much control you need.

Flux Core TypeThe flux inside the solder wire cleans oxidation from metal surfaces while you solder, helping create strong, conductive, and reliable joints. Rosin-core flux is the standard for electronics because it’s effective and leaves residues that are generally non-corrosive, though some people prefer to clean them afterward. Some solder uses 'no-clean' flux, which produces minimal residue that can safely be left on the circuit. Acid-core flux solder should never be used for electronics, as it can damage components. When picking flux type, consider how much cleaning you're willing to do after soldering, and always choose one made for electronics.

Melting TemperatureThis is the temperature at which the solder flows and creates a joint. Lower-melting solders are easier for delicate parts and require less robust soldering irons, while higher-melting solders give stronger joints but need more heat (which can risk damaging sensitive parts if you're not careful). Lead-based solders melt around 180-190°C, while lead-free solders often need 220-240°C. Pick a solder that matches the capabilities of your soldering iron and the heat tolerance of your components.

Spool SizeSpool size simply refers to how much solder you get. Small spools are convenient for light or occasional work, and they’re easier to handle or store. If you solder frequently or have large projects, bigger spools are more economical and mean fewer interruptions. Think about how much soldering you expect to do, so you don’t run out mid-project or buy more than you’ll ever use.