We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Sticker Making Machines

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Sticker Making Machines

When choosing a sticker-making machine, it's important to consider what types of stickers you want to create, the level of detail and quality you need, as well as how frequently you'll be using the machine. Understanding the key features will help you make a decision that matches your crafting goals and workflow. Rather than focusing purely on brand names or appearances, focus on the specifications that directly impact your results and the ease of use for your specific projects.Cutting SizeCutting size tells you the maximum dimensions of material the machine can handle. This is important because it sets the limits for the size of the stickers you can make in a single pass. Machines often come in categories like small (up to 5 inches wide), medium (around 9-12 inches), or large (15 inches or more). If you plan to make mostly small labels for organizing or journaling, a small cutting size will suffice and be more compact. For larger decals, wall stickers, or batch jobs, a medium or large machine will serve you better. Think about the largest project you want to tackle and make sure your machine supports at least that size.

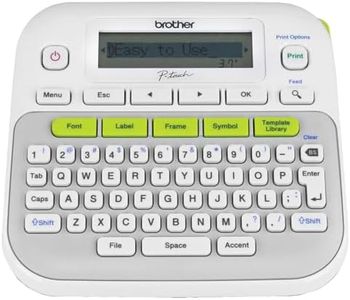

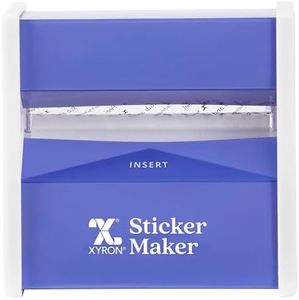

Cutting TechnologyThe cutting technology refers to the method the machine uses to cut out the stickers, most commonly manual die-cutting, digital knife cutting, or plotter-style. Manual machines need dies or cartridges, and are best for simple, repeated shapes, while digital models connect to a computer or smart device and can cut custom designs very precisely. If you prefer unique or complex shapes, or want to design your own stickers, look for digital cutting; if you mainly want simple, repeatable shapes without tech setup, manual may do the trick. Match the technology with your comfort with computers and the complexity of stickers you want to make.

Material CompatibilityMaterial compatibility indicates which sticker materials (vinyl, paper, cardstock, specialty films, etc.) the machine can successfully cut. Some machines are limited to thin stock, while others can handle thick or textured materials. If you mainly want classic paper stickers, most machines will work, but if you plan to try out glitter vinyl, fabric, holographic films or laminated sheets, check the compatibility list. Be clear about the types of stickers you envision creating, and make sure your choice supports those materials.

Print FeatureNot all sticker-making machines can print and cut in one go. Print-and-cut machines combine a built-in printer (often using inkjet technology) with a cutter, while others only cut materials you provide. If your stickers need custom images or text, you'll want a print-and-cut model; if you plan to use pre-printed designs or solid color vinyl, a cutting-only machine might work fine. Think about whether you want full design freedom—printing your own art and then cutting it—or if you'll be happy using pre-printed sheets.

Ease of Use and SoftwareThe ease of use refers to how straightforward the machine is to set up and operate, including the quality and complexity of its software or app. Some sticker machines have user-friendly apps with lots of designs included, while others require graphic design knowledge or more complicated setup. If you're a beginner, focus on machines known for their simple software and step-by-step tutorials. If you want professional-level customization or integration with design programs, prioritize advanced software options. Let your comfort with technology help guide this decision.