We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Straight Edge For Circular Saw

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Straight Edge For Circular Saw

Choosing a straight edge for your circular saw is all about ensuring clean, accurate, and safe cuts while working with wood, plywood, or other sheet materials. The right straight edge helps you guide your saw in a straight line, reduces mistakes, and boosts your confidence in DIY or professional projects. Since different tasks, workspaces, and user preferences exist, understanding the key specifications will empower you to select the tool that best suits your needs.LengthLength refers to how long the straight edge is from end to end. This is crucial because you want your straight edge to be longer than the piece you're cutting, allowing you to clamp it down securely and guide your saw through the full length of the material. Shorter straight edges (around 24-36 inches) are good for smaller boards and quick jobs, while medium lengths (48-60 inches) suit common plywood sheets and average DIY work. Extra-long edges (over 8 feet) are ideal for full-size sheets or when you need long, continuous cuts. To pick the right length, think about the largest pieces you usually cut—your straight edge should be at least as long as those, or slightly longer for flexibility.

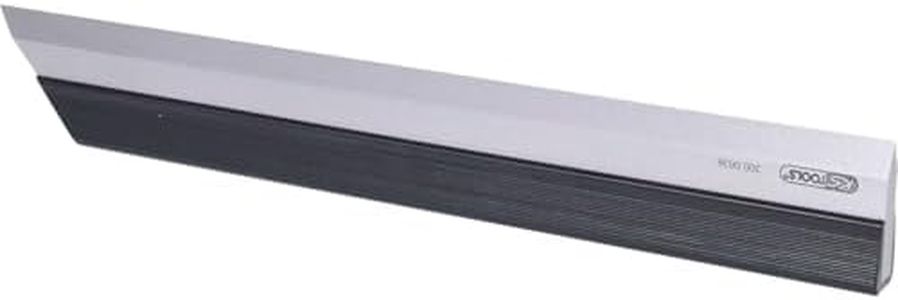

MaterialStraight edges are often made from materials like aluminum, steel, and sometimes plastic. The material affects weight, sturdiness, and durability. Aluminum is lightweight yet strong, making it easy to handle and less likely to bend, perfect for most users. Steel is heavier and offers maximum durability but may be overkill unless you're in a rough environment. Plastic is lightweight and inexpensive but can warp or nick more easily, which could affect accuracy. If you plan to use your straight edge frequently or for precise work, go for metal; for casual, light jobs, plastic may be enough.

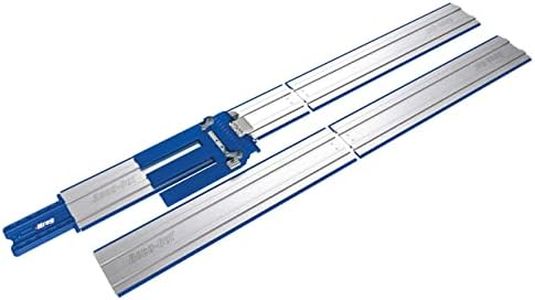

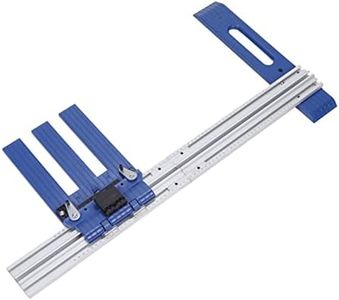

Clamping MechanismThe clamping mechanism keeps the straight edge securely in place while you cut. This spec is important because movement during a cut ruins the straightness and can be unsafe. Some straight edges come with built-in clamps, others require separate clamps. Built-in clamps are fast and convenient, ensuring better alignment and less hassle. Separate clamps may allow more flexibility in positioning but require extra setup. If you want quick, frustration-free use, look for integrated clamping; if you already have quality clamps or like to customize the setup, find an edge compatible with what you own.

Guide Track CompatibilitySome straight edges are simple rulers, while others have guide tracks that work with special saw base plates or accessories to further prevent the saw from veering off line. This spec matters if you do a lot of long or tricky cuts and want the highest accuracy. If you want to keep things simple and are comfortable controlling the saw by hand, a basic edge will do. But for extra precision or if you're not confident in keeping the saw straight manually, consider a guided track. Your experience level and the level of perfection you need should guide your choice here.

Width and ThicknessThe width and thickness of the straight edge determine how stable it feels when used and how well it resists flexing or moving. Wider, thicker edges tend to stay put and resist bending, which improves accuracy, especially on large, heavy boards. Slimmer straight edges are easier to store and lighter—but may not be as steady. If you mostly work with small wood pieces or need something easy to carry or store, a thinner edge is fine. For heavy-duty, wide, or long cuts, prioritize a thicker, sturdier straight edge.

Anti-Slip FeaturesSome straight edges come with rubber strips or textured undersides to help grip the material and prevent shifting during cutting. This feature is important to keep your cuts clean and avoid dangerous slips, especially when working alone or in awkward positions. If you prioritize both safety and accuracy, anti-slip features are a valuable addition. If you always use clamps and work on stable benches, this feature might be less essential.