We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

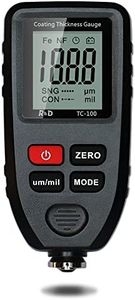

10 Best Thickness Gauge

From leading brands and best sellers available on the web.Buying Guide for the Best Thickness Gauge

Choosing a thickness gauge is all about understanding your measuring needs and the materials you commonly work with. Whether you're measuring paint on a car, metal on machinery, or coatings on various surfaces, the right thickness gauge can make your work more efficient and accurate. You'll want to consider what kind of materials you'll be measuring, the range of thickness you expect, and how precise you need your readings to be. Evaluating the important specifications will help you pick a tool that suits your applications and ensures reliable results.Measurement RangeMeasurement range refers to the minimum and maximum thickness that the gauge can accurately measure. This is important because using a gauge outside its specified range can lead to inaccurate results. Ranges can be divided into narrow (for very thin films or coatings), medium (suitable for most general work), and wide (for heavy-duty or industrial applications). To pick the right one, consider the minimum and maximum thickness you’ll encounter in your projects—always select a gauge that covers a little more than what you anticipate needing.

Accuracy and ResolutionAccuracy indicates how close the gauge's readings are to the actual thickness, while resolution is the smallest change in thickness the gauge can detect. Higher accuracy and finer resolution give more reliable and detailed measurements, which can be critical in quality control or industrial work. Gauges come in basic (good for non-critical work), intermediate (suitable for most semi-professional uses), and high-accuracy (necessary for lab or regulated industry use). Match your choice to how precise your job needs to be: for routine checks, a basic gauge may work, but for quality inspections or standards compliance, go for higher accuracy and resolution.

Material CompatibilityThickness gauges are often designed for specific materials like ferrous (magnetic metals), non-ferrous (non-magnetic metals), plastics, or coatings. Some gauges are universal, while others are specialized. It’s important because the measurement principle may vary based on the material, affecting the accuracy. If you only work with one material, a specialized gauge offers simplicity and reliability. If you need flexibility, look for a gauge that supports multiple materials or automatically detects them.

Display TypeThe display shows your measurement results. Choices typically include analog dials, digital screens, or combination displays. Analog displays provide quick, simple readings but may lack precision, while digital displays usually offer clearer, more detailed information, sometimes with additional features like backlighting or data storage. Pick a display type that matches your preference for ease of reading and the environment you’ll work in—digital is usually best for precision and low-light settings.

Probe Type and SizeThe probe is the part of the gauge that touches the material being measured. Probes come in various shapes and sizes—flat, pointed, flexible, or even detachable—each suited to different surfaces or hard-to-reach spots. If you work with flat, accessible surfaces, a standard probe is fine. For measuring in grooves, on curved surfaces, or in small areas, look for gauges with specialized or interchangeable probes.

Data FeaturesSome thickness gauges offer data recording, transfer, or analysis features. This might include memory functions, USB/Bluetooth connectivity, or companion apps. These features are helpful for professionals who need to document results, run statistics, or integrate measurements into reports. If your work involves saving or sharing data, prioritize gauges with robust data features; if you measure occasionally, simpler models are just fine.