We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Tig Welding Gloves

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Tig Welding Gloves

Choosing the right TIG welding gloves is essential for both safety and performance. TIG welding is a precise process, and your gloves must provide the right mix of protection, dexterity, and comfort. Before you buy, think about how often you’ll be welding, the type of materials you work with, and your preference for feel and flexibility in your hands. The main features you should look at will help you find the pair that best fits your hands and your type of projects.MaterialThe material of the gloves is critical because it determines protection, comfort, and finger sensitivity. Common materials include goatskin, deerskin, and cowhide. Goatskin is usually softer and offers great dexterity, making it excellent for precise movements in TIG welding. Deerskin often feels supple for comfort but may not be as durable as goatskin. Cowhide is tougher and more protective, but sometimes sacrifices flexibility. If you need maximum finger control for fine welding, softer leathers like goatskin may suit you best. If you're concerned about wear and tear, sturdier materials like cowhide might be a better pick.

DexterityDexterity refers to how easily you can move your fingers and control small welding tools while wearing the gloves. This is important because TIG welding requires steady hands and precision. Gloves with thinner, more flexible material will generally offer better dexterity, but might offer less heat protection. If your welding projects involve detailed or artistic work, prioritize dexterity. If you're doing more basic joins, you can afford slightly bulkier gloves.

Heat ResistanceHeat resistance indicates how well the gloves can protect your hands from the heat generated during welding. TIG welding doesn’t produce as much heat and sparks as some other methods, so you don’t need extremely thick gloves, but you still need some basic protection. Gloves usually have an inner lining or reinforced areas for extra heat resistance. If you frequently weld for longer periods or at higher amps, you might opt for gloves with better heat protection. For occasional or low-amp work, lighter gloves should be sufficient.

Fit and ComfortHow the gloves fit your hand affects both safety and ease of use. Too loose, and your movements may become clumsy; too tight, and you might lose feeling or tire more quickly. Some gloves have ergonomic stitching or designed finger shapes for added comfort. Be sure to pick a fit that’s snug but not restrictive, and if you have longer welding sessions, look for gloves with moisture-wicking or breathable linings to prevent sweaty hands.

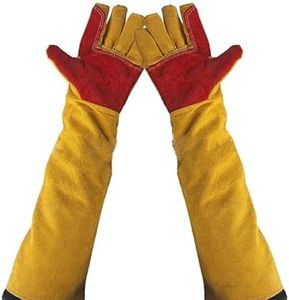

Cuff LengthCuff length refers to how far the gloves extend up your arm. Longer cuffs provide more protection for your wrists and lower forearms from sparks and heat, while shorter cuffs are lighter and less restrictive. If you often work in tight or awkward spaces, you may prefer shorter cuffs for easier movement, but if protection is your main concern, longer cuffs are better.

Stitching and ConstructionQuality stitching and sturdy construction affect how long the gloves will last and how well they protect you. Heat-resistant stitching, such as Kevlar thread, is better for welding, as regular thread can burn or fall apart. Reinforced areas (like the palm and fingers) add durability. To choose well, examine how the gloves are pieced together and look for double stitching in high-wear spots, especially if you expect to use them often.