We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

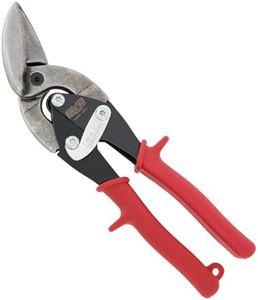

10 Best Tin Snips

From leading brands and best sellers available on the web.Buying Guide for the Best Tin Snips

Choosing the right tin snips can make a big difference in your comfort, efficiency, and the quality of your work when cutting sheet metal, wire mesh, or similar materials. Before making a choice, it's helpful to think about what kinds of cuts you’ll be making, how often you expect to use the tool, and how thick the material will be. Paying attention to the tool’s specific features will help you find tin snips that are easy to handle and tailored to your needs.Cutting TypeCutting type refers to the design of the snip and the type of cut it is meant for—straight, left (curved left), or right (curved right). Straight snips are best when you need to cut long, straight lines, while left and right snips help make smoother, controlled curves in each respective direction. Choosing the right cutting type is important because it makes the job safer and easier. If you know you’ll mostly make straight cuts, a straight snip is best. For round shapes or ductwork, pick a left or right snip accordingly. Many users keep all three to be ready for any job, but focus on the type you expect to use most.

Blade MaterialBlade material plays a role in how well the snip performs and how long it lasts. Most tin snips use steel, often hardened or treated to resist wear. This is important because harder steel stays sharp longer and is less likely to bend or chip. Some snips may have coated blades that reduce friction and protect against rust. For basic home tasks, general steel or stainless steel is ample, but if you plan regular heavy-duty use or work with tough materials, seek higher-quality, hardened steel blades for longevity.

Cutting CapacityCutting capacity indicates the maximum thickness and the type of material that the snip can safely cut, usually listed in gauge (a measurement of sheet metal thickness). It’s important because using tin snips on material that’s too thick will damage the tool and make cutting harder. Cutting capacities are segmented into light (thin sheet metal like 24-26 gauge), medium (commonly 18-22 gauge), and heavy-duty (14-18 gauge steel or similar). To pick the right one, check the thickness of the typical material you’ll cut and make sure the snip exceeds that thickness. Going for a higher capacity is good for versatility, but remember, the tool might be bulkier.

Handle DesignHandle design affects comfort, grip, and safety. Some handles are straight, others are offset or angled. Offset handles keep your hand above the material, preventing scrapes and making long cuts easier, while straight handles are more versatile but may be harder to use on large sheets. Non-slip grips or cushioned handles reduce fatigue and improve safety, especially during longer sessions. Consider what feels comfortable in your hand and whether you’ll be using the snips for extended periods.

Locking MechanismA locking mechanism holds the snips closed when they are not in use. This is important for safe storage and carrying, reducing accidental cuts and keeping the blades from getting damaged. Some locks are more secure or easier to switch one-handed than others. Choose based on your personal preference for convenience and safety, especially if you’ll keep the tool in a bag or with other tools.