We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

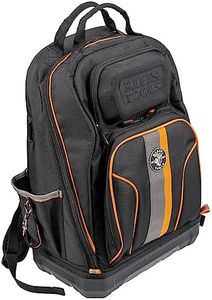

10 Best Tool Backpack For Hvac

From leading brands and best sellers available on the web.Recommended lists

Buying Guide for the Best Tool Backpack For Hvac

Selecting a tool backpack for HVAC work is all about finding a bag that can keep your tools organized, protected, and easy to transport on the job. As HVAC professionals often work in varied environments—sometimes cramped or outdoors—your choice should help you move efficiently, safeguard your equipment, and withstand tough conditions. Think carefully about the types of tools you usually carry, the layout you prefer, and how comfortable it will be to carry your gear over longer periods.Durability and MaterialDurability refers to how well the backpack can withstand the daily wear and tear of rough job sites and frequent use. Materials like heavy-duty nylon or reinforced polyester are common in quality tool backpacks, as they offer resistance to rips and moisture. If you regularly work in harsh environments, prioritize bags made from tough materials with reinforced bottoms to prevent cutting or punctures. If your work is lighter or mainly indoors, a less rugged bag may suffice.

Tool Organization and Pocket LayoutThis refers to the arrangement and number of pockets and compartments inside the backpack. Good organization allows you to quickly find the tool you need and keeps everything in place during transit. Some backpacks have dozens of specialized pockets for pliers, wrenches, meters, and more, while others are more basic. If you carry a wide range of hand tools, meters, and small parts, choose a backpack with lots of varied pockets. For simpler workflows or fewer tools, a straightforward layout with larger compartments might be better.

Carrying ComfortThis spec refers to features that make the bag comfortable to carry, like padded shoulder straps, a contoured back panel, and chest or waist straps. These are especially important if you carry heavy loads or frequently move between job sites. If your jobs require lots of walking or climbing, look for maximum padding and ergonomic features. For short transfers or lighter setups, basic straps may be enough.

Size and CapacitySize and capacity mean how much the backpack can hold, typically measured in liters or by the number of tools it can accommodate. A larger capacity fits more tools but can become bulky and heavy, while a smaller bag keeps things lightweight but may limit what you can bring. Tailor the size to the quantity and size of tools you typically take; if you need to bring power tools or diagnostic equipment, opt for a larger backpack, whereas for basic repair and maintenance, a medium or small one may be more manageable.

Accessibility and Opening StyleAccessibility is about how easily you can get to your tools. Some tool backpacks open fully like a clamshell for easy access, while others only open at the top or at a central pocket. If you frequently need quick access or like to see everything at once, go for a model that opens wide or has multiple access points. For lighter use or fewer tools, a top-loading style might be less bulky and easier to manage.

Weather ResistanceWeather resistance refers to the backpack's ability to protect your tools from rain, snow, or damp environments. Features like water-resistant zippers, a waterproof base, or a rain cover are helpful if you often work outdoors or in unpredictable weather. If most of your work is indoors, this may be less critical, but a minimal level of resistance can still protect your tools from occasional splashes.

Additional FeaturesThese are extra conveniences like hard-sided compartments for fragile instruments, external loops or holders for tape, and slots for laptops or tablets. Consider what special tools or tech you need to carry and check if the backpack design supports those needs. If you use electronic devices on the job, a padded electronics sleeve can be especially useful.