We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

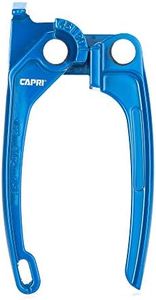

10 Best Tubing Bender For Brake Lines

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Tubing Bender For Brake Lines

When searching for a tubing bender for brake lines, your goal is to find a tool that's both easy to use and suitable for the precise, small-diameter pipes used in vehicle braking systems. You'll want a bender that creates smooth bends without crimping or damaging the tube, ensuring the brake line maintains its strength and shape. Balancing size, material compatibility, and ease of operation is key to getting clean, professional-looking results while working safely.Supported Tubing SizesThe supported tubing sizes refer to the diameter ranges of brake lines the bender can handle, usually measured in inches or millimeters. Choosing the correct size range ensures that your tool grips and bends your brake lines properly, preventing slippage or tube deformation. Benders may support small diameters such as 3/16”, 1/4”, and 5/16”, which are common for automotive brake lines. Evaluate what tubing size your braking system requires, and pick a bender that matches those dimensions for the best fit and results.

Bend Radius CapabilityBend radius capability describes the tightness of the curve the bender can make without kinking the tube, typically listed as a minimum bend radius. This is crucial because too-tight bends can restrict fluid flow or weaken the tube. Tools designed for gentle, larger-radius bends are safer for novice users and critical applications like brake lines. If your project needs sharp bends in tight spaces, choose a tool that supports smaller radii, but always confirm it won't compromise tube integrity.

Supported MaterialsThis refers to the types of tubing materials the bender can handle, such as steel, copper, aluminum, or nickel-copper alloys. Each material has its own hardness and flexibility, so it’s important to match the bender to your tubing material. Check your vehicle or project requirements—if it's steel brake lines, make sure the bender is rated for steel. Multi-material benders offer versatility, but always verify compatibility for the specific tubes you’ll use.

Ease of UseEase of use covers the design aspects that make bending simpler and more accurate, such as comfortable grips, clear angle markings, and leverage mechanisms. Tools designed for two-handed or three-handed operation allow for more control, helpful for both beginners and those working in tight spaces. Consider your comfort level and workspace: if you're new or have limited room, seek out a simple, ergonomic design that minimizes effort and learning curve.

Bending Angle RangeThe bending angle range tells you how far you can bend the tube in a single operation, typically up to 90 or 180 degrees. The broader the angle range, the more flexibility you have for various projects. Think about the types of bends your brake lines require. For most repair or replacement work, being able to achieve 90-degree bends smoothly is essential, but some setups may need tighter or more complex curves, so a wider angle range may be valuable.