We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Using Epoxy Resin

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Using Epoxy Resin

When it comes to selecting epoxy resin for your project, it's important to understand that not all resins are the same. Epoxy resin is commonly used in arts, crafts, home repairs, woodworking, and industrial applications for its durability and attractive finish. The wide variety of choices can seem overwhelming at first, but focusing on the specs that matter most for your particular use will help you make the best choice. Think carefully about the type of project you are doing—is it art, coating a tabletop, making jewelry, fixing something, or casting deep molds? Each use may have different ideal resin properties. By considering these factors, you can ensure that the epoxy resin you choose gives the best results possible for your needs.Curing TimeCuring time refers to how long epoxy resin takes to harden after being mixed and poured. This spec is important because it affects how quickly you can handle or use your finished item. Epoxy resins usually fall into fast-cure (hardens in a few hours), standard-cure (takes 12–24 hours), and slow-cure (may take several days). Fast-cure is handy for small, quick crafts or urgent repairs, but it might not allow much time to work or fix mistakes. Standard-cure suits general uses and provides a good balance of workability and speed. Slow-cure is best for large pours or projects where you want bubbles to rise and escape, or when layering colors or effects. Your project size and how patient you can be should guide your choice—bigger pieces need longer cure to minimize heat build-up, while smaller items can benefit from a fast set.

ViscosityViscosity measures how thick or runny the epoxy resin is when you mix it up. This matters because viscosity affects how the resin flows into molds, over surfaces, or mixes with pigments. Low viscosity (thin, like syrup) is ideal for deep pours, woodworking fills, and casting where you need the resin to penetrate cracks or fully encapsulate objects. Medium viscosity is a good all-round choice for coating surfaces or making jewelry, letting you control coverage without being too runny. High viscosity (thick, like honey) is mainly for surface art or applications where you want the resin to hold its shape and not run off. Think about what you want your resin to do—filling, flowing, or staying in place—and pick the viscosity that matches.

UV ResistanceUV resistance describes how well the cured resin can handle exposure to sunlight or strong indoor lights without turning yellow or becoming brittle. This property is important for anything that will be displayed in a sunny spot or used outdoors, such as jewelry, art, or tabletops. Some resins have special additives to block UV rays, while others do not. If your piece will see a lot of sun, go for a resin labeled as UV-resistant or non-yellowing; for items kept in the dark, standard epoxy can work just fine. Your intended use—indoor or outdoor, shaded or in sunlight—should determine how much UV resistance you need.

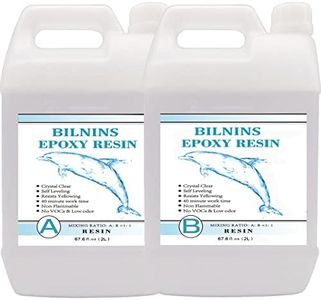

Mix RatioMix ratio indicates how much resin and hardener you need to combine for a proper cure. Most common ratios are either 1:1 (equal parts) or 2:1 (two parts resin to one part hardener), but some specialty epoxies use other ratios. This spec is important because a precise mix is crucial for full curing and overall strength. A simple 1:1 ratio is easier for beginners and most art or craft projects, while different ratios can offer specialist properties like improved flexibility or faster cures. If you're new to resin, look for a straightforward ratio to avoid mistakes and ensure a successful result.

Working Time (Pot Life)Working time or pot life refers to how long you have after mixing the resin and hardener before it begins to set and becomes too thick to work with. This is important because it determines how much time you have to pour, spread, or manipulate your resin before it starts to harden. Short working times mean you need to work quickly, which suits small, simple pieces or quick repairs. Longer working times let you do large pours, detailed art, or work at a slower pace. Consider the size and complexity of your project to select a resin that gives you enough time to work comfortably.

ClarityClarity describes how clear or see-through the cured resin is once it hardens. This spec is particularly important for art, jewelry, river tables, and anything where you might embed objects or use color pigments. High-clarity resins create a glass-like, transparent finish that's desirable for showpieces or layered effects. Some resins may cure slightly cloudy, so if absolute transparency is needed, look for resins advertised as 'water-clear' or 'crystal clear.' If you're painting, adding solid colors, or using the resin for repairs, super high clarity might not be necessary.