We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Vinyl For Shirts

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Vinyl For Shirts

Choosing the right vinyl for making shirts can be the difference between a project you're proud of and one that doesn’t last after a few washes. There are many types of vinyls designed specifically for apparel decoration, and it’s important to understand the differences so you make something durable, comfortable, and attractive. By paying attention to the major characteristics of vinyl, you’ll find picking the best option for your shirts much easier.Type of VinylThe type of vinyl refers to the base material and how it adheres to fabric. The main kinds are Heat Transfer Vinyl (HTV) and adhesive vinyl. HTV is specially made for clothing because it uses heat (from iron or a press) to stick to fabric, ensuring a strong bond that lasts. Adhesive vinyl, on the other hand, is better for hard surfaces and not suitable for shirts. So, always choose HTV if your project is on fabric. Among HTVs, there can be standard, stretch, glitter, flocked, or printable types. The best one for you depends on whether you need flexibility, texture, sparkle, or the ability to print your own designs. Think about your intended look and comfort—if the shirt will be worn often or needs to stretch, ‘stretch’ HTV is ideal. For decorative touches, glitter or flocked choices stand out.

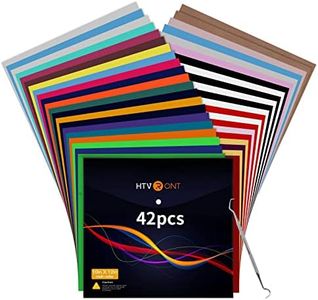

FinishFinish describes how the vinyl looks and feels once applied. The most common are matte, glossy, glitter, foil, and flocked. Matte finish gives a subtle look that blends in with the shirt, while glossy has a shiny appearance that stands out. Glitter and foil add sparkle or a metallic shine, making designs pop, while flocked vinyl offers a fuzzy, velvety surface for unique designs. Your choice should reflect the style you want—go for matte or glossy for everyday wear, and glitter, foil, or flocked for special or eye-catching projects.

ThicknessThickness is how dense and sturdy the vinyl sheet is, usually measured in microns or mils. Thinner vinyl (around 50-90 microns) feels softer and more like part of the shirt, which is good for comfortable clothing or layering multiple colors. Thicker vinyl (over 100 microns) can be easier to work with and more durable, but can feel stiff or heavy against the body. Consider how the shirt will be used—if you want a soft feel and flexibility, go thin; for workwear or heavy-duty projects, a thicker vinyl might be better.

Ease of WeedingWeeding is the process of removing extra vinyl from your design before placing it on your shirt. Some vinyls are engineered to make this easier—especially helpful for detailed or intricate patterns. If you plan to work with small text or fine details, look for vinyl advertised as ‘easy to weed’. This will save you frustration and time, especially if you’re a beginner or making many shirts.

Washability and DurabilityWashability and durability indicate how well the vinyl stays on after repeated washing and wearing. High-quality vinyl is designed to last through many laundry cycles without peeling, cracking, or fading. This is particularly important for shirts that will be worn and washed often. Look for vinyls marketed as ‘durable’, ‘wash-tested’, or ‘fade-resistant’. Matching the level of durability to the shirt’s intended use—everyday versus special occasion—will help you pick the right option.

Application Temperature and PressureEvery vinyl has a recommended temperature and pressure for application, which ensures it adheres correctly to fabrics. Some vinyls need high heat and strong pressure, while others are designed for lower settings (ideal if you’re using a basic home iron rather than a heat press). Match the vinyl with what equipment you have available—if you own a heat press, you can choose from almost any vinyl; if you’re using a household iron, stick with vinyls that specify lower application temperatures.