We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Waterproof Tape For Outdoor

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Waterproof Tape For Outdoor

Choosing the right waterproof tape for outdoor use involves understanding how the tape will hold up against moisture, temperature changes, sun exposure, and the type of surface you want to repair or seal. Your selection should be based on matching the features of the tape to your task, whether it’s patching a leaky pipe, sealing a roof, or fixing outdoor gear. It’s important to focus on key specifications that determine how effective the tape will be under real outdoor conditions.Adhesion StrengthAdhesion strength means how well the tape sticks to surfaces; it is crucial because outdoor repairs are often exposed to wind, rain, and physical stress. Adhesion can be described as low, medium, or high. Low-strength tapes work for temporary holds or smooth surfaces, while medium strength is fine for light repairs. High-strength adhesion is ideal for rough, uneven, or high-stress situations where a long-lasting seal is needed. Consider what you’re taping—if it’s exposed to a lot of movement or weather, go for stronger adhesion.

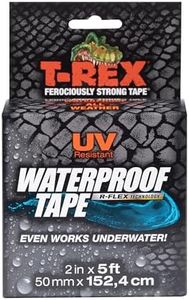

Waterproofing AbilityThis spec shows how well the tape keeps water, moisture, or humidity out. Not all waterproof tapes offer the same level of water protection—some are only water-resistant, while others are fully waterproof and can be submerged. If you need to seal a surface that might get splashed or rained on, water-resistant may suffice. But for patches on boats, pipes, or pools, fully waterproof options that can handle submersion are better. Think about the expected water exposure when choosing your tape.

UV ResistanceUV resistance is the tape’s ability to resist damage from sunlight. Outdoor tapes without UV resistance can crack, fade, or lose stickiness over time. Tapes are usually labeled as non-UV, moderate UV, or high-UV resistant. For short-term outdoor fixes or shaded areas, moderate resistance is enough; for long-term exposure in sunny places, always look for high UV resistance to ensure durability.

Temperature ToleranceTemperature tolerance tells you the range of temperatures the tape can handle without losing its properties. If a tape’s range is narrow, it might harden in the cold or melt in extreme heat. Tapes can be divided into those made for moderate climates and those built for harsh, freezing, or scorching conditions. Pick higher tolerance for spots like rooftops, vehicle repairs, or anything that gets really hot or cold.

FlexibilityFlexibility refers to how easily the tape can conform to curves and uneven surfaces. Some tapes are stiff and best for flat, straight lines, while flexible tapes can wrap around pipes, hoses, or textured surfaces. If your repair area is curved or has an odd shape, choose a tape known for its flexibility. For flat, uniform areas, this is less critical.

Backing MaterialThe backing material, usually plastic, rubber, or fabric, affects both durability and how easy the tape is to remove. Plastic or polyethylene films are common for waterproofing, while fabric backings offer extra strength but may not be completely waterproof. If you need ruggedness and moisture protection, choose a sturdy plastic or rubber-based tape. Fabric-backed options are better for temporary fixes or light-duty applications.