We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Welding Blankets

From leading brands and best sellers available on the web.Buying Guide for the Best Welding Blankets

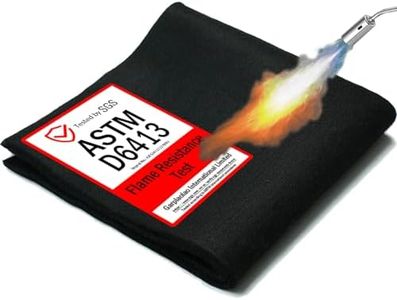

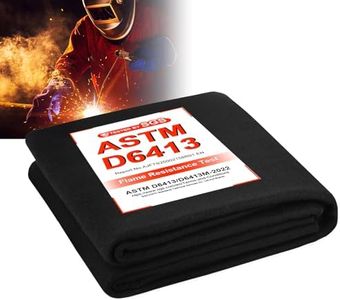

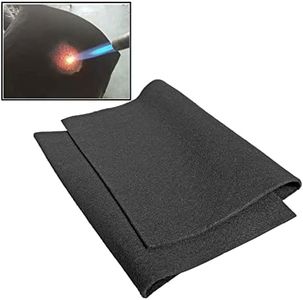

Choosing the right welding blanket is very important for both safety and effectiveness when working with welding, cutting, or grinding tasks. The main job of a welding blanket is to protect people, equipment, and surfaces from sparks, spatter, and heat. Welding blankets come in several types and materials, each suited for different tasks and environments, so understanding the key specs will help you pick the best one for your needs.MaterialWelding blankets are made from materials like fiberglass, silica, carbon fiber, or ceramic. Each material offers different levels of heat and flame resistance. For example, fiberglass blankets are common and provide good heat resistance for most light- to medium-duty welding. Silica blankets handle higher temperatures and are used in more intense operations. Carbon fiber and ceramic blankets are suited for extremely high-temperature environments. When picking a material, think about the type of welding you do and the temperatures you expect. If you’re working on light repairs, fiberglass might be okay, but for industrial or heavy work, consider silica or carbon fiber.

Temperature RatingThis spec tells you the maximum temperature the blanket can safely handle. Blankets typically range from about 1000°F to over 2500°F. Lower ratings are fine for simple tasks like soldering, while higher ratings are needed for heavy-duty welding or plasma cutting. Be sure to match the temperature rating of the blanket with the most extreme job you plan to do. Picking a blanket with a higher rating than you need adds extra safety.

ThicknessThickness affects both heat resistance and flexibility. Thicker blankets (around 1/4 inch or more) provide better protection against high temperatures and sparks, but can be stiffer and harder to drape over objects. Thinner blankets are more flexible, easier to handle, and work well for lighter duties. Choose thickness based on what you’re protecting; heavy equipment or critical surfaces need more thickness, while routine projects can use thinner, lighter blankets.

SizeBlankets come in many sizes to cover everything from small work areas to large machines. It’s important to select a blanket that’s big enough to fully shield your work area, people, or equipment from stray sparks. If unsure, measure the area you need to protect and pick a blanket that provides full coverage, with a little extra to allow for shifting or draping.

CoatingSome blankets come with special coatings like vermiculite or silicone. These coatings improve fire resistance, reduce irritation from fibers, help repel liquids, or make the blanket last longer. If you’re working in an environment with lots of spatter or sparks, or where the blanket might get wet, a coated blanket can give better performance. If comfort or durability is important for you, for example if you use the blanket a lot, selecting a coated model is a good idea.

Grommets or Fastening FeaturesMany welding blankets have grommets (metal-reinforced holes) or sewn-in loops on the edges. These make it easier to hang, secure, or tie down the blanket. This spec is more about convenience; if you need to hang the blanket vertically, or fasten it around awkward shapes, look for one with grommets or loops. If you're only laying it flat, this may not be so critical.