We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Wire Cutter For Jewelry Making

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Wire Cutter For Jewelry Making

Selecting the right wire cutter for jewelry making is essential because the right tool makes your work neater, more precise, and less physically taxing. When shopping, pay close attention to the type and thickness of wire you'll be cutting, as well as how much control and comfort you need. The ideal cutter should feel comfortable in your hand, deliver clean cuts, and be durable enough for the materials you plan to use.Cutting CapacityCutting capacity refers to the thickness (or gauge) of wire the cutter can handle efficiently and cleanly. This is crucial because using a cutter that can't handle your chosen wire might damage both the tool and your work. Generally, smaller gauges mean thicker wires, so wire cutters list their maximum cutting gauge. Thin, delicate wires common in beadwork need cutters for fine gauges (like 24-30 gauge), while sturdier rings or sculptural jewelry may need a tool rated for heavier gauges (like 16-20 gauge). Choose a cutter that comfortably fits the range of wire most common in your projects.

Type of Cut (Flush vs. Bevel)There are mainly two kinds of cuts: flush and bevel (or standard). Flush cutters produce a smooth, flat end, which is ideal for most jewelry work as it minimizes extra finishing. Bevel cutters usually make a pointed or rougher edge. If you want finished-looking ends that are less likely to scratch the skin or catch on fabric, go for flush cutters. For general-purpose wire snipping where edge quality doesn't matter, bevel cutters can do the job. Consider what finishing you prefer or are willing to do.

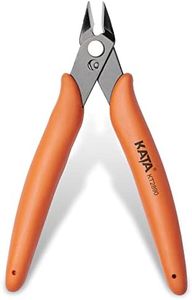

Handle Comfort and GripHandle design influences how comfortable the wire cutter is to use, especially during long crafting sessions. Ergonomic, padded, or non-slip handles help reduce hand fatigue and prevent slipping. If you have smaller hands or work for long periods, lightweight and slim-handled cutters may be more comfortable. If grip strength is an issue, look for cushioned or spring-loaded handles. Always consider how the handle feels in your own hand as it can make a big difference in ease of use.

Durability and Blade MaterialThe blade material affects how long the cutters stay sharp and how well they hold up to repeated use. Hardened steel or high-carbon steel blades resist wearing and nicking. Cheap materials can dull quickly, especially if you cut harder wires. If you work mainly with softer metals (like copper or silver), you can get by with standard steel. But for tougher metals (or if you want a longer-lasting tool), opt for cutters advertised as high-quality steel or with a hardened edge.

Size and Tip PrecisionThe size and tip shape of a cutter determine how closely and precisely you can cut in tight spaces or near beads. Fine tip or micro cutters allow for detailed work in cramped areas, perfect for intricate designs. Larger cutters provide more force but may not fit into small spaces. Think about the scale of your jewelry—if you mostly do dainty, precise work, a smaller, fine-tipped cutter is best. For chunkier, structural pieces, standard tips can be more appropriate.