We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

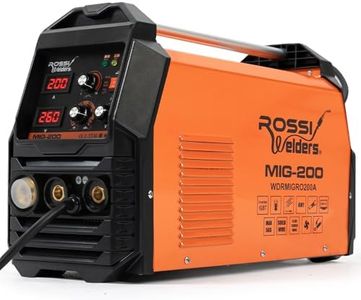

10 Best Wire Welders

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Wire Welders

Choosing the right wire welder can make welding projects easier, safer, and more enjoyable. Wire welders are popular for their ease of use, especially for beginners and hobbyists, but their features vary widely. When picking a welder, think about what kinds of projects you plan to work on, the thickness of the materials you’ll weld, and where you’ll use the welder. Understanding key specifications will help you match a machine to your actual needs, ensuring you don’t overspend or struggle with an underpowered tool.Amperage RangeThe amperage range tells you how much electrical current the welder can output, which directly affects the thickness of metal it can weld. Low amperage (below 100A) is good for thin sheet metal, while higher ranges (above 140A) can handle thicker materials and bigger projects. If you mostly do automotive or thin metal work, lower amperage might be fine; for structural work or thick steel, look for higher output. Choose based on the materials and types of welding jobs you expect to tackle most often.

Duty CycleDuty cycle is the percentage of a 10-minute period that the welder can operate before needing to cool down. For example, a 20% duty cycle at 90A means you can weld for 2 minutes continuously at 90A, then the machine must cool for 8 minutes. Higher duty cycles are important for longer welds or heavy projects, while short, occasional welds are fine with a lower duty cycle. Think about how often and how long your welds usually take, and pick accordingly.

Input VoltageInput voltage is the kind of electrical outlet the welder plugs into. Most household outlets are 120V, which limits the power and thickness you can weld. Some welders offer dual voltage, such as both 120V and 240V, allowing more versatility for bigger jobs or access to different workspaces. If you have only standard outlets and do light work, 120V might be enough, but for thick materials or workshop use, the option for higher voltage is worth considering.

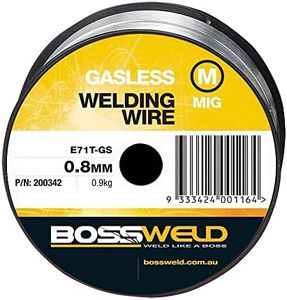

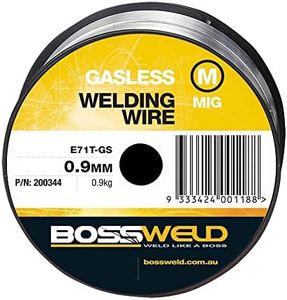

Welding Process Type (MIG/Flux Core)Wire welders often are either MIG (which uses shield gas) or flux-cored (which uses self-shielding wire). MIG gives cleaner, more precise welds but needs gas tanks, which adds complexity. Flux core is easier for outdoor work or dirty/rusty metals since it works without external gas. Consider where you'll be welding and the kind of finish you want to choose the method that matches your needs.

Wire Feed Speed ControlWire feed speed determines how quickly wire is pushed into the weld. Adjustable controls give more flexibility for different types and thicknesses of metal. Machines with only a simple, fixed setting are easier to use but less versatile. If you plan to weld a range of metals and thicknesses, get one with a wide, adjustable feed speed, but for occasional, simple jobs, a basic control will do.

Portability and SizePortability describes how easy it is to move the welder around. Smaller, lighter welders are easier to carry for on-site repairs or to move around your garage, while bigger machines are heavier but often more powerful. Consider whether you need your welder to travel with you or stay in one place; size and weight could make a big difference in convenience.