We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Air Filtration For Laser Engraver

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Air Filtration For Laser Engraver

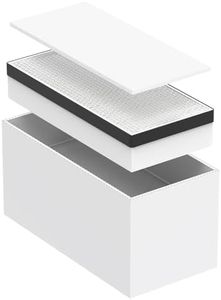

Choosing the right air filtration system for a laser engraver is essential for both safety and optimal performance. Laser engraving can produce fumes, particles, and odors that can be harmful to your health and can damage your equipment if not properly filtered out. When selecting an air filtration system, it's important to understand which features matter most to your workspace, engraving volume, and the types of materials you commonly use. A good match will ensure a comfortable, clean, and hazard-free environment.Filtration StagesFiltration stages refer to the number and types of filters a system uses to clean the air. More stages generally mean better filtration, as each stage targets different pollutants (like large debris, fine particles, or gases). Commonly, you’ll see systems with at least two or three stages, such as a pre-filter for big particles, a HEPA filter for small particulates, and an activated carbon filter for odors and gases. If you work with materials creating strong fumes, more stages with specialized filters can be helpful. For basic engraving, a dual-stage system might suffice, but complex or high-volume work benefits from three or more stages.

Airflow Capacity (CFM)Airflow capacity, usually measured in Cubic Feet per Minute (CFM), indicates how much air the system can process. Higher CFM means the unit can move more air, which is critical for larger enclosures, frequent projects, or heavy-duty machines. Small desktops or hobbyist engravers might only need low to moderate airflow, while industrial users or those with enclosed setups should seek higher capacity to prevent buildup of fumes and debris.

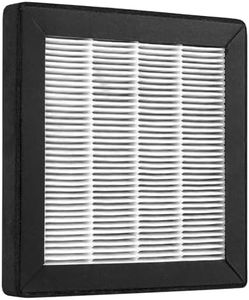

Filter Type and GradeThe type of filters, such as HEPA (for fine particles) or activated carbon (for chemical fumes), determines what pollutants the system effectively removes. The grade of these filters, like 'True HEPA' vs. 'HEPA-type,' can influence performance. For projects with lots of smoke or hazardous fumes, True HEPA and ample activated carbon are a must. Moderate users or those working with less-toxic materials can consider less intensive filtration, but should not compromise if sensitive to air quality.

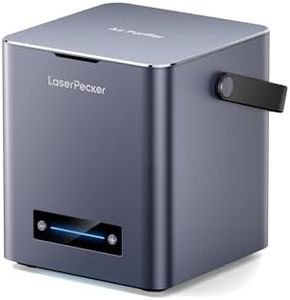

Noise LevelNoise level tells you how loud the filtration system operates, usually measured in decibels (dB). Some systems are very quiet, while others can be quite loud, potentially disrupting your workspace. If you’ll be running the filter for long periods or in a shared space, seek out quieter systems. For dedicated workshops away from living areas, a higher noise level might be less of a concern.

Filter Replacement & MaintenanceFilter replacement frequency and ease of maintenance matter for long-term use. Some filters last longer than others, and easier access for swaps can save time. If you engrave daily or with difficult materials, expect to change filters more often. Look for systems with clear replacement indicators and easily accessible filters if you value convenience.

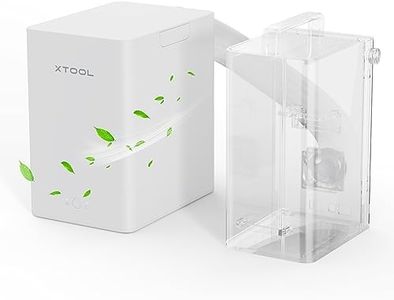

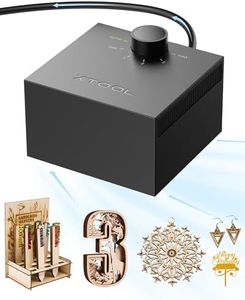

Form Factor and CompatibilityForm factor means the size and shape of the filtration unit, as well as how it connects to your engraver setup. Compact and portable units suit small desks and hobby users, while larger units with flexible ducts fit industrial setups. Ensure the system fits your space and can connect to the laser engraver enclosure for maximum efficiency.