We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

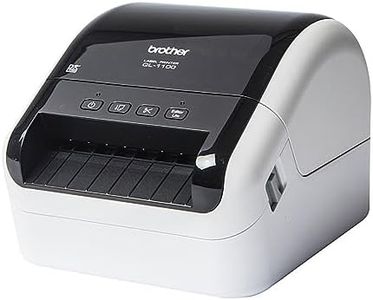

10 Best Barcode Printers

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Barcode Printers

Choosing the right barcode printer is essential for businesses looking to streamline inventory, manage sales, or improve logistics. Barcode printers come in various types and are optimized for different volumes, label sizes, and environments. Understanding how each specification affects performance and compatibility with your business needs will help you make a smart purchase. Always consider how often you'll use the printer, what types of labels you'll need, and the environment in which the printer will operate. This will help you find a model that balances performance, durability, and ease of use.Printing TechnologyThis spec refers to the method the printer uses to create barcodes—typically either direct thermal or thermal transfer. Direct thermal printers use heat to print directly onto special heat-sensitive paper, making them great for short-term labels like shipping labels. Thermal transfer printers use a ribbon to transfer ink onto a label, resulting in more durable prints suitable for product labeling or outdoor use. Consider direct thermal for temporary needs or a thermal transfer model for longer-lasting, more resilient labels.

Print ResolutionPrint resolution is measured in dots per inch (DPI) and determines how crisp and clear your barcodes and text will appear. Common values are 203, 300, or 600 DPI. Lower DPI is fine for basic shipping labels, but if you need to print small barcodes or detailed graphics like logos, a higher DPI gives better clarity. Assess the types of labels you need—simple barcodes require less detail, but retail or high-density information labels benefit from higher resolutions.

Print SpeedPrint speed indicates how quickly a printer can produce labels, typically measured in inches per second (IPS). Faster printers are better suited to high-volume environments like warehouses or busy retail shops, while slower speeds may suffice for smaller operations or where label output is less frequent. To choose the right speed, think about your daily printing demands—higher throughput needs demand higher speeds, while occasional use doesn't require top-tier speed.

Label Size CompatibilityThis spec covers the range of label widths and lengths the printer can handle. Some printers are designed for small, narrow labels while others can print much larger ones. It's important to match the printer to the sizes of labels you commonly need. For example, for small product tags, a compact label range is fine, but shipping or inventory management may need models that handle wider or longer labels.

Connectivity OptionsConnectivity refers to how the printer interfaces with your computers or network. Common options include USB, Ethernet, wireless (Wi-Fi), and sometimes Bluetooth. USB is simplest for single-computer setups, Ethernet is great for multiple users on a network, and wireless or Bluetooth options offer flexibility for placement. When deciding, consider how and where you'll be connecting the printer—shared spaces and remote access typically benefit from network or wireless options.

Durability and Duty CycleDurability indicates how robust the printer is and its duty cycle reflects how much use it's designed for (daily or monthly print volume). Light-duty printers are meant for offices or small businesses, while industrial models are built for warehouses or manufacturing, able to withstand dust, heat, and high usage. Your workload is the best guide here—choose a model whose build quality and capacity match your expected label printing frequency and environment.

Media HandlingThis relates to the types of materials (media) the printer can use, such as labels, tags, or wristbands, and whether it can handle rolls or fanfold stacks. Some printers offer features like automatic cutters or peelers for added convenience. If your needs include specialty labels or you want to automate label application, check that the printer supports these features and media types.