We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

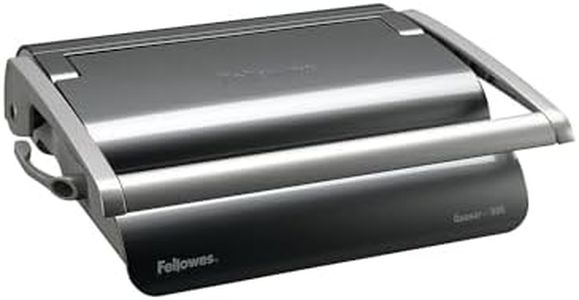

10 Best Coil Binding Machines

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Coil Binding Machines

Choosing a coil-binding machine is all about matching the device to your specific binding needs, whether it’s for occasional home projects, regular office use, or professional document production. By understanding the main features and specs of coil-binding machines, you’ll be able to select one that makes your binding tasks efficient, neat, and tailored to your workflow.Punch CapacityPunch capacity refers to the number of sheets a coil-binding machine can punch at once. This spec matters because it directly affects how quickly and easily you can prepare documents for binding, especially if you need to bind large volumes. Machines with lower punch capacities (generally 6-10 sheets per punch) work well for light tasks or occasional home use, while mid-range machines (12-20 sheets) are good for small to medium offices. High punch capacities (over 20 sheets) are suitable for frequent or professional binding jobs. Choose based on how many and how often you need to bind—if you only handle a few documents at a time, a lower capacity is fine, but for frequent or big jobs, higher punch capacity saves significant time and effort.

Binding CapacityBinding capacity tells you the maximum thickness of document (number of pages) the machine can handle when inserting the coil. This is important if you plan to bind large manuals or catalogs. Binding capacity is usually measured by the biggest diameter coil the machine supports, which translates to a certain page number (for example, up to 450 sheets). If you typically need to bind small reports, low capacity is sufficient; for larger documents, choose a model that accommodates bigger coils.

Manual vs. Electric OperationSome machines require manual punching (you pull a handle), while others offer electric punching for less physical effort. Manual machines are usually smaller, less expensive, and suitable for light use. Electric options provide faster, easier punching with minimal effort, ideal for busy environments or frequent binding. Consider how much work you want to do by hand and how many documents you'll bind regularly—a manual machine is great for occasional jobs, electric machines shine when productivity and speed matter.

Coil Insertion TypeCoil insertion can either be manual (you twist the coil through the holes by hand or with an included aid) or electric (a built-in roller feeds the coil in for you). Manual insertion is simple and sufficient for low-volume projects, but can be tiring if you have a lot of binding to do. Electric inserters make the process much faster and more comfortable, perfect for bigger jobs or frequent binding. Decide on this based on how much ease and automation you want during the binding process.

Hole Pattern and PitchThe hole pattern (spacing between punched holes) must match the coil you intend to use; most common is 4:1 pitch (four holes per inch). This affects compatibility—if you buy coils separately make sure they fit your punch pattern. Some machines let you adjust the pitch for different coil types. For most general office or school use, standard 4:1 machines are a safe bet, but if you have specific needs (like special-sized documents), you might need a machine with adjustable options.

Document Size SupportThis spec tells you the maximum size of paper the machine can handle, typically letter size (8.5 x 11 inches), but some machines can handle legal, A4, or custom paper sizes. Make sure the machine accommodates your most common paper size, especially if you use non-standard papers for your projects.

Durability and Build QualityA sturdy, well-built machine will last longer, especially if used heavily. Machines made with metal parts are more durable than all-plastic ones. If you plan to use the machine regularly or in a shared environment, prioritize build quality. For light or occasional home use, this may be less critical.