We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Hotwire Foam Cutters

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Hotwire Foam Cutters

Choosing the right hotwire foam cutter is all about matching your needs with the right set of features. Whether you’re working on model making, crafting, insulation shaping, or hobby projects, the right tool will help you work safely and efficiently. Before buying, consider what size and type of foam you’ll be cutting, how precise your work needs to be, and how frequently you plan to use the cutter. Understanding the main features will help you make a confident choice for your specific projects.Wire Temperature ControlWire temperature control lets you adjust how hot the cutting wire gets, which is important because different types and thicknesses of foam need different levels of heat to cut cleanly without melting too much or leaving burnt edges. Entry-level cutters may have a fixed temperature, meaning you can only cut certain kinds of foam, while advanced models offer temperature adjustment so you can fine-tune to your project’s needs. For occasional or simple projects, a simple control is usually enough. If you plan to work with different foams or need precise, clean cuts, look for a cutter with adjustable temperature.

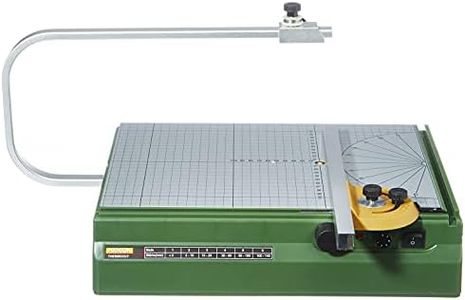

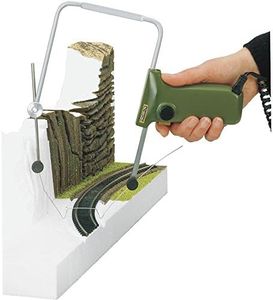

Cutting Length and DesignThe cutting length refers to how wide or deep a piece of foam you can cut in one go, which is determined by the size and shape of the cutter’s frame or arm. Small, handheld cutters are best for fine detail work and small pieces, while larger stationary or bow-style cutters allow you to make long, straight or curved cuts across big sheets of foam. Think about the typical size of your projects—if you work with large sheets of foam, a larger cutting area will save time and increase accuracy. For crafting, modeling, or intricate jobs, something smaller and more maneuverable is a better fit.

Power SourceHotwire foam cutters are usually powered either by batteries or by plugging into an electrical outlet. Plug-in models are typically more powerful and better for longer, heavier jobs, as they can deliver consistent heat without worrying about battery life. Battery-powered or USB-powered cutters are more portable and convenient for short or small projects, especially if you need to work away from a workshop or power supply. Decide where you’ll be using your cutter most often and how much portability matters.

Wire Replacement and DurabilityThe cutting wire in these tools doesn’t last forever and will eventually need replacement, especially with frequent use or cutting tough foams. Some cutters have easily replaceable wires, while others make swapping them out more difficult. If you expect to use the cutter regularly, look for a design that makes wire replacement simple, and consider whether replacement wires are easy to find. Also, pay attention to the build quality of both the wire and the frame—the sturdier the construction, the longer your tool will last and the smoother it will cut.

Safety FeaturesBecause the wire heats up to high temperatures, safety features are crucial. Some cutters have insulated, heat-resistant handles or automatic shut-off functions to minimize the risk of burns or accidents. Others may offer guards or shields around the wire. If you have kids, pets, or plan to work in a shared space, safety features should be a top priority. Even for experienced users, these features reduce the chance of accidents and make working with the cutter more comfortable and reliable.