We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

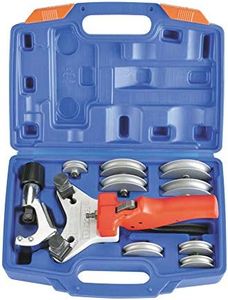

10 Best Hvac Tubing Bender

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Hvac Tubing Bender

Choosing the right HVAC tubing bender is key for anyone working with heating, ventilation, and air conditioning copper or aluminum tubing. The right tool makes the difference between neat, efficient bends that don’t damage pipes and frustrating, kinked results. When shopping for a tubing bender, you'll want to focus on matching the tool's capabilities with the types of jobs you'll most often do, the tubing sizes you'll encounter, and how much portability you need. Understanding the main features will help you confidently select the tool that will give you the best results and easiest use for your HVAC needs.Tubing Size CapacityTubing size capacity refers to the range of tube diameters a bender can handle effectively. This is important because HVAC systems use various tubing sizes, and using the wrong bender can damage the pipe or create inaccurate bends. Tubing benders typically come rated for small (1/4 to 3/8 inch), medium (1/2 to 3/4 inch), and large (1 inch or more) diameter tubes. If you mostly work on residential HVAC systems, you’ll encounter smaller diameter tubes, while commercial or large-scale work might require handling thicker pipes. Always match the bender’s capacity with the most common tube sizes you work with to get professional and reliable bends.

Bend Radius CapabilityBend radius capability indicates the tightness of the curve a bender can make without kinking the tube. It’s important because a too-tight bend can restrict air or fluid flow or weaken the tubing. Tubing benders are usually categorized into fixed radius (standard curves) and variable radius (can adjust to tighter or more gradual curves). If your projects require precise bends in tight spaces, look for a tool with a smaller minimum bend radius. For general work or gentle curves, a standard fixed radius bender will suffice. Consider the tightest spaces you need to work in to help guide your choice.

Manual vs. Powered OperationThis refers to whether you operate the bender by hand or if it uses a mechanical or electric assist. Manual benders are straightforward, portable, and ideal for lighter jobs or field work. Powered benders offer greater consistency and make bending thicker or harder tubing easier, but they’re usually bulkier and less portable. Think about whether you need to bend heavy tubing frequently or if portability and simplicity are more important based on your worksite conditions.

Degree Markings and AccuracyDegree markings show you how far you’ve bent the tube, helping ensure consistency and accuracy—important for creating multiple identical bends. Some benders have clear, easy-to-read markings for common angles like 45° and 90°, while others may require guesswork. If your work involves precise installations or repeated bends, prioritizing a bender with accurate, visible degree markings will save time and mistakes. For simple or occasional use, less detailed markings may suffice.

Durability and Construction MaterialDurability and construction material refer to what the bender is made from—commonly aluminum, steel, or reinforced composite. This affects both tool lifespan and performance. Steel benders are heavier but more robust for regular or heavy-duty use, while aluminum tools are lighter, offering portability for lighter jobs. Consider how often and intensively you’ll use the tool: choose a heavier-duty build for daily work or a lighter construction for occasional use or easier transport.