We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

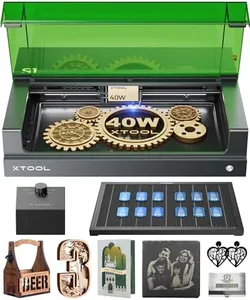

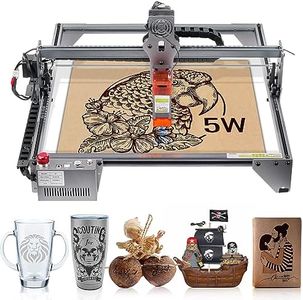

10 Best Leather Laser Engraving Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Leather Laser Engraving Machine

Choosing a leather laser engraving machine can be a rewarding investment if you want to add intricate designs, patterns, or personalizations to leather items like wallets, belts, bags, or even small accessories. The right machine can make your projects easier, more precise, and efficient. When shopping for a leather laser engraver, focus on understanding what features make the biggest difference for your specific projects, such as the thickness and type of leather you plan to use, how detailed your designs will be, and the scale of work you want to handle. Don't get overwhelmed by technical jargon; focus on specs that affect performance and usability for your needs.Laser Power (Wattage)Laser power, usually measured in watts (W), indicates how strong the laser beam is. For leather, you'll typically see machines ranging from 20W to 100W or more. Lower power (around 20-40W) is suited for thin leather and finer engraving or cutting. Medium power (40-80W) covers most crafts, giving a good balance for thicker materials and moderate speed. Higher power (above 80W) is mainly for professionals or large-scale operations. Pick based on the thickness of leather you plan to engrave and how fast or deep you want the engraving to be; hobbyists often need less power than commercial users.

Working Area SizeThe working area is the maximum surface the machine can engrave or cut in one pass, usually measured in millimeters or inches. Smaller areas (like 200x200 mm) are best for small items or personal projects, while medium (around 400x600 mm) suits wallets, purses, or signage. Large working areas (600x900 mm and bigger) are ideal for bulk production or bigger pieces. Choose a machine size that fits most of your planned projects, so you don’t hit size limits or waste space.

Type of LaserThe laser source affects the types of materials you can work with and the quality of the engraving. CO2 lasers are common for leather, as they produce clean cuts and detailed engravings. Fiber lasers are not typically used for leather. Among CO2 lasers, sealed tube designs last longer and are low-maintenance. For most users working primarily with leather, a CO2 laser is best; make sure that's what the machine uses unless you need a machine for more materials.

Precision and Resolution (DPI)Precision refers to how accurately the laser can engrave details, often listed as DPI (dots per inch) or a minimum spot size. Lower DPI (around 200-400) is enough for simple patterns, while higher DPI (500-1000+) allows for fine, detailed images or small text. If you plan on doing detailed artwork or tiny lettering, look for higher precision; for basic logos or large patterns, standard resolution is fine.

Compatibility and ConnectivityThis is about how you send designs to the machine and what software you can use. Some machines work with USB, others with Wi-Fi or Ethernet, and many require you to use their specific software while some allow use of common design programs. Pick based on what design software you like to use and whether you need easy connections for a home or workshop environment. Make sure your computer and preferred image formats are supported.

Safety FeaturesLaser engravers can produce fumes, heat, and intense light, so safety is crucial. Look for features like an enclosed laser bed, automatic shutoff, smoke extraction or filtration, and emergency stop buttons. If you're working indoors or around other people, strong safety features are a must. For occasional use in well-ventilated areas, simpler safety options may be enough—but always prioritize your health and safety.