We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

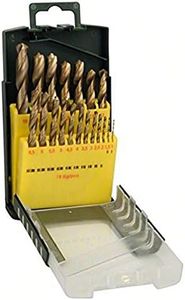

10 Best Metal Drill Bits

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Metal Drill Bits

Choosing the right metal drill bit can make your drilling tasks much easier and produce better results. It's important to match the drill bit to both the type of metal you'll be working with and the equipment you have at hand. By understanding the key specifications, you'll avoid mistakes like damaging your project, breaking bits, or ending up with messy holes. The best way to pick metal drill bits is to consider what metals you plan to drill most often, how powerful your drill is, and how often you expect to use the bits.MaterialThe material a drill bit is made from determines how hard and heat-resistant it will be, which affects what kinds of metals you can drill. Common options include high-speed steel (HSS), cobalt, and carbide. HSS bits are a general-purpose choice, suitable for softer metals like aluminum and mild steel—they’re affordable and easy to sharpen. Cobalt drill bits are tougher and can handle harder metals like stainless steel without dulling quickly, although they tend to be more brittle. Carbide bits are extremely hard and stay sharp the longest, but they are best reserved for very demanding jobs and are usually used with specialized equipment. Consider how tough the metal you’ll be drilling is, and match the bit material to it for the best results.

CoatingCoatings on drill bits provide an extra layer that can reduce friction, prevent overheating, and increase lifespan. Common coatings include black oxide, titanium nitride, and cobalt finishes. Black oxide offers some corrosion resistance and is suitable for general work. Titanium coatings help bits last longer and drill faster, making them good for repetitive work on harder metals. A cobalt blend (which is technically not just a coating) means the hardness goes all the way through, so the bit keeps performing even after sharpening. If you tend to drill often or work with tougher materials, prioritize better coatings or cobalt for more efficiency and durability.

Bit SizeThe size of the drill bit refers to its diameter and determines the size of the hole you’ll create. Drill bits come in a wide range of sizes, from tiny fractions of an inch or millimeter to large sizes for heavy-duty work. For most users, basic sets with a variety of common sizes are enough, but for special tasks or thicker materials, larger diameter bits might be needed. Check the size requirements for your specific project or fastener and choose bit sizes that match those measurements—having a variety makes your toolkit more flexible.

Tip AngleThe tip angle of a metal drill bit affects how easily it penetrates different metals and stays centered as you drill. Common angles are 118 degrees and 135 degrees. A 118-degree tip is a good all-rounder, especially for softer metals and general drilling. A 135-degree split point is ideal for harder metals and helps prevent the bit from wandering or slipping on smooth surfaces. Choose the tip angle by considering the type of metals you often work with and how much accuracy you need during starting.

Shank TypeThe shank is the part of the bit that goes into the drill chuck. Shank types include straight shank and reduced (or shanked) diameter. Most home drills use straight shank bits, which come in a range of sizes. Reduced shank bits allow you to use larger-diameter bits with a standard-sized drill chuck. Make sure the shank matches the type and size of your drill’s chuck for a secure fit and safer operation.

Flute DesignFlutes are the grooves running along the body of the drill bit and they help remove metal chips from the hole as you drill. Standard bits have two flutes, which is good for most tasks. For deeper or faster drilling through thicker metals, longer flutes or special designs might help clear waste more efficiently. If you work mainly with thin sheets, standard flute design is sufficient; if you drill deeper holes often, look for bits with optimized flute design for chip removal.