We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

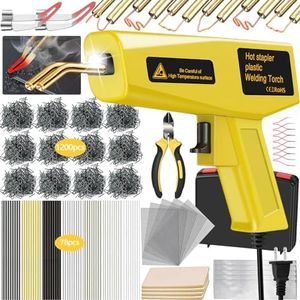

10 Best Plastic Welders

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Plastic Welders

Choosing a plastic welder isn't just about picking the most powerful tool you can find; it’s about matching the type of welding, heat source, and control features to the kind of plastic repairs or projects you’ll be handling. Think about if you’re going to work on automotive repairs, household items, plumbing, or crafts—different tasks might require different welding types and settings. Getting the right welder can save you time, deliver better results, and help you avoid damaging your materials.Type of Welding MethodThe welding method refers to how the plastic welder joins pieces together—common methods include hot air, ultrasonic, solvent, and friction welding. Each has unique strengths: hot air is the most versatile for DIY and repairs, ultrasonic is fast and clean for precise or industrial work, and solvent works for certain plastics by effectively 'gluing' them at a chemical level. To pick the right method, think about your materials (soft or hard plastics), the thickness of your projects, and whether you need a quick or careful finish. For general home use, hot air welders are often the easiest to start with.

Temperature ControlTemperature control is the ability to adjust and maintain heat levels while welding. This spec is crucial because different plastics melt at different temperatures, and overheating can burn or warp your material. Some welders let you dial in precise temperatures, while others have only a few preset options. Beginners or those working with various plastics should look for models with adjustable temperature ranges, while those mostly welding one type of plastic could manage with a simpler control.

Power Output (Wattage)Power output, measured in watts, tells you how much heating ability the welder has. Higher wattage generally means faster heat-up times and the ability to handle thicker plastics. Small repairs or thin materials don’t need lots of power, while larger, frequent projects or industrial tasks benefit from higher wattage. If you only deal with lightweight repairs, a lower wattage may suffice; for heavier duty or large-scale welding, go higher.

Nozzle and Tip VarietyNozzle and tip variety refers to the different shapes and sizes of attachments that control the flow and spread of heat or plastic. A welder with more tips can handle a wider range of repair scenarios and plastic types—fine tips are great for precision work, while wide or flat tips spread heat over larger areas. Consider your typical project: if you do detailed work or repairs in tight spaces, look for a kit with multiple nozzles.

Compatibility with Plastic TypesNot all plastic welders work with every kind of plastic—some are better with specific materials like ABS, PVC, or PP. This compatibility is determined by both the temperature range and the welding method. It's important to know which plastics you’ll most often repair, and check that the welder you choose can handle those materials without causing them to degrade.

Ease of Use and Safety FeaturesEase of use covers how simple and comfortable the welder is to handle, including weight, grip, and controls. Safety features may include thermal cut-outs, insulated handles, or built-in stands. If you’re a beginner or will use the tool for extended periods, prioritize welders with ergonomic handles and automatic shut-off to avoid fatigue and accidents.