We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

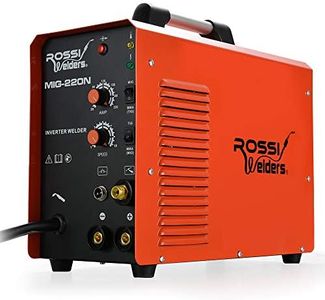

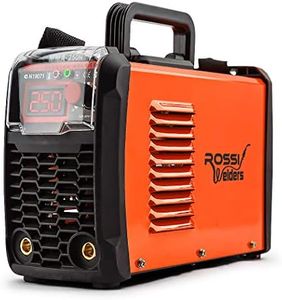

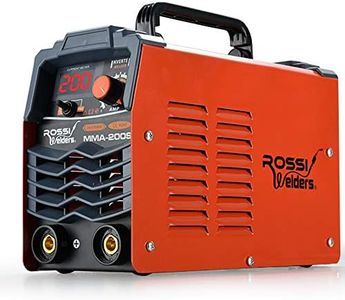

10 Best Portable Welding Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Portable Welding Machine

Choosing a portable welding machine can feel overwhelming, but focusing on your specific needs and understanding the key specifications will help you select the best fit. Start by thinking about the materials you plan to weld, the environments where you’ll work, and your level of experience. Remember, the right welder should not just be easy to carry, but also capable of handling your projects safely and efficiently.Welding Process TypeThe welding process type refers to how the machine joins metals and determines what jobs it’s best suited for. Common types include Stick (SMAW), MIG (GMAW), and TIG (GTAW). Stick welders are generally versatile and good for outdoor work or thicker materials, while MIG welders are easier for beginners and work well with thin materials. TIG is ideal for high-quality, precise welds, often used with stainless steel or aluminum. Consider the thickness and type of metal you often use—if you need versatility, a machine supporting multiple processes could be ideal.

Amperage RangeThe amperage range tells you how powerful the welding machine is, and directly affects the thickness of metal you can work with. Lower amperage (20-80A) is suitable for thin materials like automotive panels, medium range (80-180A) covers most standard fabrication jobs, and high amperage (over 180A) is meant for thick structural steel. To choose the right amperage, match it to the typical thickness of materials you expect to weld most frequently.

Input VoltageInput voltage is the type of electrical power the welder requires: usually 110/120V or 220/240V, and some models offer dual-voltage support. Lower voltage is common in standard outlets at home and suitable for light projects, while higher voltage means more power for heavy-duty work, often found in workshops. Pick a machine with an input voltage compatible with your most common work environment and power sources.

Portability (Weight & Size)Portability covers the size and weight of the welding machine, making a big difference if you’ll move it regularly. Lighter models (under 20 lbs) are easiest to carry for quick repairs on-site or at different locations, while heavier machines (over 30 lbs) might be better for a dedicated workspace. Think about how often you’ll need to transport your welder—if you expect to carry it often or work in tight spaces, go for a lighter and more compact option.

Duty CycleDuty cycle is how long you can use the welder within a ten-minute period before it needs to cool down, often listed as a percentage. For example, a 30% duty cycle at 90A allows you to weld three minutes out of every ten. Lower duty cycles are fine for light, occasional use, while a higher duty cycle (over 60%) is important for longer or professional-grade projects. If you expect to work in long bursts or do production welding, a higher duty cycle is better.

Built-in Safety FeaturesBuilt-in safety features protect both you and the machine. Look for things like thermal overload protection, which shuts the unit off if it overheats, and voltage fluctuation protection, which keeps the machine running safely on unstable power. If you’re a beginner or working in unpredictable environments, prioritizing good safety features can help prevent accidents and equipment damage.