We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

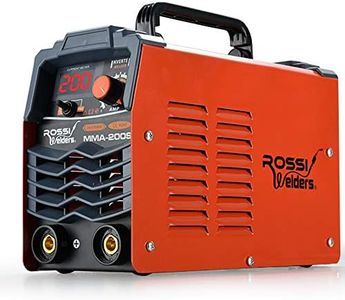

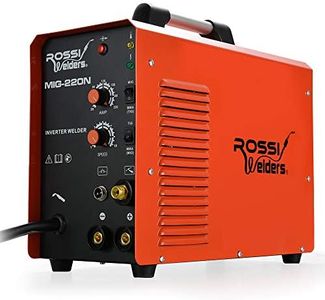

10 Best Welding Machines

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Welding Machines

Choosing the right welding machine can make your projects easier, more efficient, and safer. With so many types and features available, it's important to understand which specifications matter for your intended use. Identify the kind of welding you want to do, the materials you'll be working with, and the level of experience you have, then focus on the specs that align with those needs. Taking the time to compare these factors ensures you end up with a tool that matches both your current requirements and your skill growth over time.Welding Type (Process)The welding type refers to the process the machine is designed for, like MIG, TIG, Stick, or Multi-process. This is important because each welding method works best with certain materials and skill levels. For example, MIG is user-friendly and efficient for general tasks, TIG is excellent for precision and thin materials, and Stick is great for outdoor or rougher jobs. If you want versatility, a multi-process machine handles several types. Think about your usual projects—if you often work with thin metals or want clean welds, TIG might suit you. For fast, easy welds on various materials, MIG could be better. Your primary use case should guide your choice.

Amperage RangeAmperage, or output current, determines how much power the welding machine provides, directly affecting the thickness of material you can work with. A low amperage range is suitable for thinner metals, while higher outputs are needed for thicker steel or even aluminum. If you mainly plan to weld thin sheet metal, a machine with a lower range works well. For heavy-duty or industrial projects, look for a higher amperage range. Match the amps to your most common materials to ensure consistent, effective welds and avoid over or underpowered machines.

Input VoltageThis spec tells you what kind of power the welder needs—commonly 110/120V for household outlets, 220/240V for more demanding machines, or both for flexibility. Lower voltage options are easy to use at home but may have limits on power, while higher voltage is required for robust or continuous work and thicker metals. If your worksite has industrial power or you expect to weld heavy gauge metal, pick higher input voltage. For home or light use, standard household voltage models are usually enough.

Duty CycleThe duty cycle tells you how long the machine can run in a 10-minute period before needing a break to cool down. For example, a 30% duty cycle at a certain amperage means it can weld for 3 minutes then needs 7 minutes to cool. A high duty cycle is best if you plan to weld for long stretches, like for large or professional projects. For short or occasional use, a lower duty cycle is sufficient. Choose a duty cycle that will keep up with your pace to avoid frustration and downtime.

Portability and WeightPortability is about how easy it is to move or transport your machine, which depends on both its physical weight and whether it has handles or wheels. Lightweight machines are great if you work in different locations or have limited storage, while heavier units may be sturdier but harder to move. If you'll be welding in various spots, portability is essential; for stationary work, it's less important. Consider your workspace and how often you'll need to move your welder.

Material CompatibilityThis covers the types of metals—like steel, stainless steel, or aluminum—the machine can weld. Some machines are more versatile, while others are specialized. It's important to pick a machine that handles the most common materials you plan to work with. For example, if you want to weld aluminum, make sure the machine offers this capability. Check this before you buy to avoid limitations in your projects.