We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

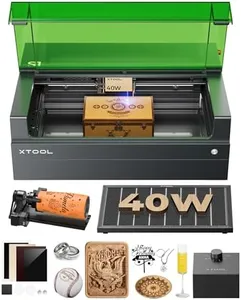

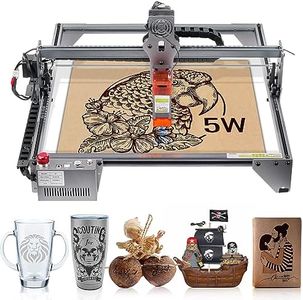

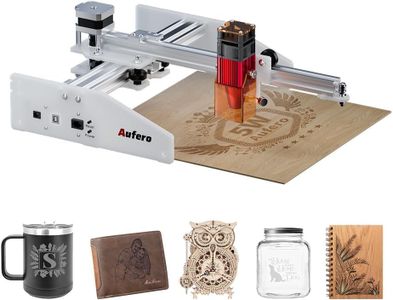

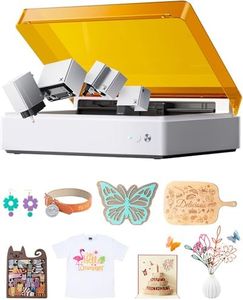

10 Best Small Laser Cutter

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Small Laser Cutter

Choosing a small laser cutter can be exciting but also overwhelming if you are new to the field. The key to making a good choice is understanding how you'll use the cutter: Are you working on crafts, signage, personalized gifts, or small-scale prototypes? Size, safety, cutting ability, and ease of use are all crucial factors. Think about the materials you’ll cut or engrave, the size of the pieces, the detail of your designs, and how comfortable you are with setting up and operating technical equipment. The aim is to find a laser cutter that fits seamlessly into your workflow, giving you great results with as little hassle as possible.Laser Power (Wattage)Laser power, measured in watts, tells you how strong the laser is. Higher wattage lets you cut through thicker or tougher materials and usually means faster cutting. Small laser cutters often range from about 5W to 40W. If your main use is engraving on paper, leather, or thin wood, lower power is usually fine and can give you better detail. For cutting through thicker wood, acrylic, or light metals, go for a higher power. Your choice here depends on what materials and thicknesses you want to work with most often.

Work Area SizeThe work area size is the maximum area the laser can cut or engrave in a single go. Think of it like your 'canvas.' Small laser cutters can have work areas as little as 8x8cm up to about 40x40cm. Choose a bigger work area if you plan to make larger items or batch projects. If you’re only interested in smaller trinkets, jewelry, or custom engraving, a small area will be more compact and easier to fit in your workspace.

Supported MaterialsNot all lasers can cut or engrave every material. Common supported materials include wood, plastic, leather, paper, fabric, and sometimes metal (for engraving, not cutting). Check what materials the cutter is rated for, as using the wrong one can damage the machine or create toxic fumes. Match the cutter’s capabilities to your intended projects—if you plan to do mostly wood and acrylic, pick a model known for handling those materials safely and efficiently.

Safety FeaturesLaser cutters can be hazardous without the right protections. Look for features like enclosed work areas, built-in ventilation, emergency stop buttons, and safety interlocks. Some have sensors to pause cutting if the lid is opened. Choose the right safety levels by considering where you’ll use the cutter, who might be around (children, pets), and your own comfort with handling machines.

Ease of Use/Software CompatibilityLaser cutters need design files, often made with specific software. Some have their own user-friendly software, others rely on third-party options. If you’re new to laser cutting, seek a machine with simple controls and clear instructions, and check for compatibility with your preferred design software (like Illustrator or free alternatives). This spec helps you avoid frustration and ensures you can get creative without a steep learning curve.

Maintenance NeedsAll laser cutters need upkeep, such as cleaning lenses, checking the laser tube, and clearing debris. Some are almost plug-and-play, while others require more regular attention. Think about how much time and effort you want to spend maintaining your machine. If convenience is important, look for models known for easy care, with accessible components and good support materials.