We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

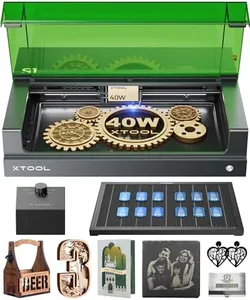

10 Best Small Laser Engraver For Metal

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Small Laser Engraver For Metal

Choosing a small laser engraver for metal can be exciting, as these machines allow for precise markings, customizations, and creative projects on various metal items. To get the best engraver for your needs, consider how you plan to use it—whether for hobbyist crafts, personalized gifts, or small production runs. The right engraver should match the types of metals you'll work with, the amount of detail you want, and the space you have available. Understanding key features will help you make an informed decision and enjoy reliable, quality results.Laser Power (Wattage)Laser power refers to how strong the laser beam is, usually measured in watts (W). This is important because a higher wattage means the engraver can mark or etch deeper and faster, and it can handle harder metals more easily. Low-power engravers (under 5W) are good for thin metal surfaces and fine, shallow marks, while mid-range lasers (5W-20W) offer more flexibility for slightly harder materials and deeper engraving. High-power units (above 20W) can engrave faster and go deeper into tougher metals. Think about what metal items you want to engrave and how detailed or deep you want the markings—choose a power level that matches these needs.

Working Area SizeThe working area is the physical space on the platform where you can place items to be engraved. A larger workspace lets you engrave bigger items or multiple smaller objects at once, but takes up more room on your table. Small engravers often have working areas between a few centimeters to about 20 x 20 centimeters. If you mainly want to engrave small charms, tags, or jewelry, a compact area is usually enough. If you think you'll want to work with bigger pieces or do larger projects, aim for the bigger end of that range.

Laser Type (Fiber, Diode, CO2)Lasers used for metal engraving come in different types: fiber, diode, and CO2. Fiber lasers are especially good for metals, offering high precision and marking speed—they can engrave most metals effectively. Diode lasers are more affordable and compact, but often weaker and usually suitable for coated or softer metals unless specially designed. CO2 lasers are not typically used for bare metals; they are better for non-metal materials unless the metal has a special coating. For best results with metal, especially if you want clean, permanent engravings, fiber lasers are usually preferred, while diode is a good entry point for lighter use.

Engraving SpeedEngraving speed tells you how quickly a laser can mark the material, usually measured in millimeters or inches per second. Faster speeds mean you can finish projects more quickly, which is helpful for small business use or if you want to do many engravings in a short time. For very detailed jobs or deep engraving, slower speeds provide more control and quality. Think about whether you need to make a lot of pieces quickly, or if precision and detail matter more to you—choose an engraver that can balance both as needed.

Supported MaterialsNot all small engravers can handle all types of metals. The manufacturer's guide will often list which metals can be engraved, such as stainless steel, aluminum, brass, copper, or precious metals. Some lasers will only work well with coated or anodized metals, so if you need to engrave bare or a wide variety of metals, check that the engraver is capable. It's important to match the engraver's capability with the exact types of items you want to mark—for broader options, a unit that supports many metals is ideal.

Software CompatibilityThe engraver uses software to control the design, text, and settings for engraving. This spec is about what kind of programs the machine can run with, which affects your design flexibility and ease of use. Some machines require proprietary apps, while others work with popular graphic design tools or accept files like SVG, JPG, or DXF. If you have experience with certain design software, check for compatibility. If you’re new to engraving, look for user-friendly, well-supported software to make your experience smoother.

Safety FeaturesLaser engravers can be dangerous if not used properly, especially with strong lasers and metal reflections. Important safety features include protective shields, automatic shut-off, eye protection (goggles), and enclosure options. These help prevent accidental exposure to the laser beam, which can be harmful to eyes and skin. If you are new or planning to use the engraver around others or in a shared space, prioritize machines with robust safety features to keep everyone protected.

Cooling SystemEngraving lasers generate heat during use, so a built-in cooling system (like fans or liquid cooling) helps keep the machine running safely and extends its lifespan. Compact engravers might have just a fan, while more advanced ones include active cooling for high-power operation. If you’ll be running long or frequent engraving jobs, or if your workspace is not well-ventilated, pick an engraver with effective cooling to avoid overheating and ensure consistent performance.