We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

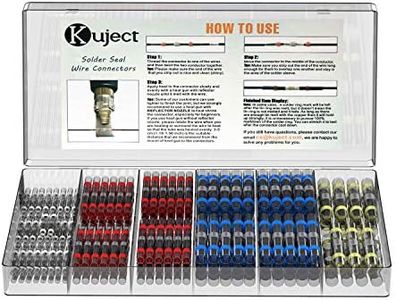

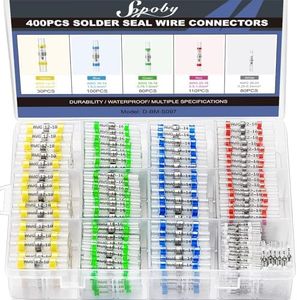

10 Best Solder Seal Wire Connectors

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Solder Seal Wire Connectors

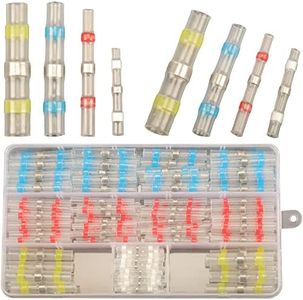

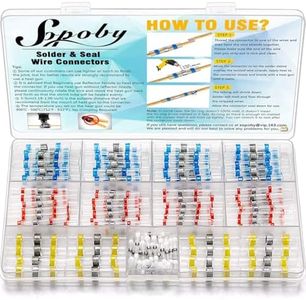

Choosing the right solder-seal wire connectors is all about matching your needs for secure, long-lasting wire joins, especially in automotive, marine, or DIY electrical projects. The connectors simplify wiring tasks by combining heat-shrink tubing, solder, and insulation in one component. This ensures that you get strong electrical connections without the need for advanced skills or lots of tools. Recognizing your project type and where the connectors will be used helps guide your choices.Wire Gauge CompatibilityWire gauge compatibility refers to the range of wire sizes that a solder-seal connector can properly join. It's crucial because using the wrong size may cause unreliable connections that could fail or cause overheating. Connectors are often labeled for certain wire gauge ranges, such as 10-12 AWG (thicker wires), 14-16 AWG (medium), or 22-18 AWG (thinner wires). For safety and performance, always match the connector to the size of wire you are using. If you commonly work with a variety of wire sizes, consider a set that includes multiple gauge options.

Waterproofing and SealingWaterproofing is the capability of the connector to resist moisture ingress after installation. This is essential if you plan on using the connectors in environments exposed to water, such as marine or outdoor automotive work. Most solder-seal connectors include a heat-shrink tubing that melts and forms a seal around the wire, keeping out moisture. Some have an adhesive lining for extra protection. If reliability outdoors or in damp conditions matters to your project, prioritize connectors specifically marked as waterproof or featuring adhesive-lined heat shrink.

Solder QualitySolder quality refers to the metal ring inside the connector that melts and bonds your wire ends together. Good solder ensures a strong electrical connection and reduces the risk of breaks or poor conductivity. Some connectors have more solder than others, or use different alloys. If you need more robust or higher-current connections, check for brands known to use high-quality or ample solder. For basic tasks or occasional use, most standard connectors will suffice, but if reliability is paramount, invested time checking reviews or manufacturer claims about solder performance.

Ease of UseEase of use involves how simple the connector is to position and use with a heat source (such as a heat gun). Some connectors shrink and melt the solder quickly and evenly, while others may require more time, care, or a very precise heat setting. If you're new to solder-seal connectors or want faster, hassle-free installations, look for ones noted for quick shrinkage and reliable melting with common heat guns. If your projects are intricate or in tight spaces, pick connectors with clear tubing and visible solder so you can see when the connection is made.

Insulation MaterialThe insulation material is the outer tubing that covers the wire joint. It’s important because it determines the durability, flexibility, and resistance to heat or chemicals. Most are made from polyolefin, which offers good balance between flexibility and toughness, but some are more resistant to abrasion or chemicals if your environment is especially harsh. If your work area is exposed to oils, fuels, or movement, choose connectors with sturdy insulation. For general wiring, standard polyolefin is usually fine.