We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Stick Welding Gloves

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Stick Welding Gloves

Choosing the right stick welding gloves is crucial for both safety and comfort. Stick welding, also called Shielded Metal Arc Welding (SMAW), produces a lot of heat, sparks, and radiation, so your hands need maximum protection. The best welding gloves balance durability, dexterity, heat resistance, and comfort. To make the right choice, you should consider the materials, insulation, fit, and special features. Thinking about how often you weld, the type of work you do, and the environment you work in will guide your decision.MaterialThe material of stick welding gloves is important because it determines the level of heat resistance, flexibility, and durability of the gloves. Most stick welding gloves are made of leather—like cowhide, pigskin, or goatskin. Cowhide is thick and durable, best for heavy-duty protection but less flexible. Goatskin is thinner and more flexible, offering better dexterity but a bit less protection from extreme heat. Pigskin balances flexibility and toughness and is naturally resistant to moisture. For stick welding, thicker leathers like cowhide are generally preferred since they offer the protection required.

Insulation and LiningThe lining inside welding gloves adds an extra layer of heat protection and comfort. Common linings include cotton, fleece, and special heat-resistant materials. Heavily insulated gloves excel at shielding hands from high heat but can sometimes reduce your ability to feel and maneuver small objects. Lighter linings offer more dexterity but less protection for prolonged welding. If you do lots of stick welding or work on high-amperage jobs, go for heavy insulation. For shorter, lighter jobs, a less insulated glove could work and allow for better movement.

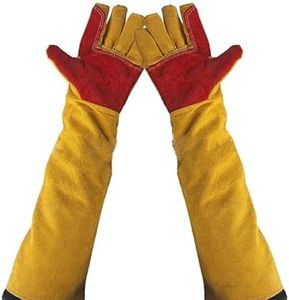

Cuff LengthCuff length refers to how far the gloves extend up your arm. Longer cuffs protect your wrists and lower forearms from sparks and hot metal. Stick welding can produce flying debris, so gloves with longer cuffs (often called gauntlet cuffs) are usually best. Shorter cuffs are less protective but more comfortable in tight spaces. If you work in open areas or do overhead welding, a longer cuff is safer. If space is tight or you do precision work, you might opt for a medium-length cuff.

Fit and DexterityFit is how snugly the gloves mold to your hand, while dexterity is your ability to move your fingers and grip objects. A too-loose glove can be unsafe because it might catch on things or limit your control, while a glove that's too tight can restrict movement and quickly become uncomfortable. Try on gloves or check sizing charts to find a balance: you want them snug enough for control but roomy enough for comfort and movement. If you handle small tools or need detailed control, prioritize dexterity. For heavy welding where safety trumps agility, a bulkier glove is acceptable.

Stitching and ReinforcementsThe type of stitching and presence of added reinforcements affect the glove's durability and heat resistance. Strong, heat-resistant threads (like Kevlar stitching) keep the gloves from falling apart under high temperatures and heavy use. Reinforced palms and fingers provide extra protection in the areas that wear out fastest. If you weld often or for long periods, look for gloves with reinforced stitching and patches. For occasional use, basic but sturdy construction will suffice.