We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Welding Wire

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Welding Wire

Choosing the right welding wire is crucial because it directly affects the strength, appearance, and durability of your welds. Different projects, metals, and welding techniques require specific types of wire for the best results. Understanding the key specifications helps you match the right wire to your job, avoiding problems such as weak welds or excess splatter.Wire MaterialWire material refers to what the wire is made of, such as mild steel, stainless steel, or aluminum. This matters because you generally need to match your wire material to the material you are welding. For example, mild steel wire is used for regular steel projects, stainless wire for stainless steel, and aluminum wire for aluminum parts. Choosing the correct material ensures the weld is strong and appropriately resistant to rust or corrosion for your specific application.

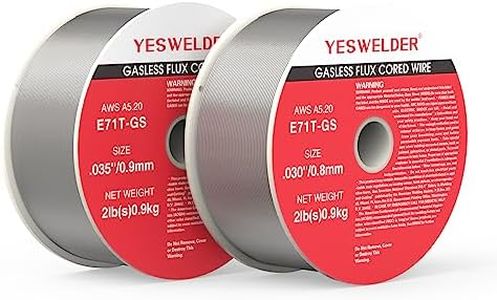

Wire DiameterWire diameter is the thickness of the wire, most commonly measured in millimeters or inches. Thinner wires (like 0.6mm or 0.023 inches) are easier to control and suit lighter, thinner metals or more detailed work. Thicker wires (like 1.0mm or 0.045 inches) are used for heavier metals and can handle higher currents and deeper welds. The right diameter depends on both the thickness of what you’re welding and your welder’s settings; thinner workpieces require thinner wire to prevent burn-through, while thicker materials call for thicker wire for strong welds.

Wire Type (Solid vs. Flux-Cored)The type of wire can be solid (for use with shielding gas) or flux-cored (which has a core that acts as its own shield). Solid wire is best for indoor welding with cleaner metals and makes clean, precise welds. Flux-cored wire works well outdoors or on dirty/rusted metals because it creates its own protection from the environment, and is often easier for beginners. Your choice here depends on where you’ll be welding and the cleanliness of your metal—pick the type that fits your working conditions.

Spool SizeSpool size is about how much wire comes in one roll, often measured in pounds or kilograms. Smaller spools are easier to handle and switch out, suitable for hobbyists or smaller projects. Larger spools are more cost-effective and reduce how often you need to stop to reload, making them better for frequent or industrial use. The right spool size depends on how often you weld and if your machine has restrictions on spool size.

Wire ClassificationWire classification refers to industry codes (like ER70S-6 for steel wire) that tell you about the wire’s chemistry and suitable use. Each code signals what metals and welding conditions the wire is made for. Understanding these lets you confidently pick a wire that matches your project’s demands for strength, ductility, and corrosion resistance. Look up what the classification means for the wire you're considering, and match it to the recommendations for your project material.