We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Wires Stripping Machines

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Wires Stripping Machines

When buying a wire stripping machine, your main goal is to find a tool that helps you remove the insulation from electrical wires quickly and efficiently, whether for recycling, electrical work, or crafting. Carefully considering the key features will make sure the machine you pick is suitable for the wires you work with and offers the ease of use, safety, and durability you need. It's important to evaluate what types of wires you plan to strip, how much work you intend to do, and the work environment you'll be in. This process involves matching the machine’s capabilities with your specific requirements, ensuring a smoother and more effective operation.Wire Size CapacityWire size capacity determines what diameter and range of wires the machine can handle. This is crucial because not all machines can strip both thin household wires and thick industrial cables. Wire size capacity is usually given in a range, such as from a certain minimum to a maximum diameter. Smaller machines are suited for thin wires, while more robust models can handle thicker cables. Choose a machine that supports the wire sizes you work with most—if you strip a variety, a machine with a wide capacity range could be best.

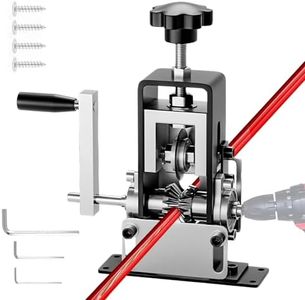

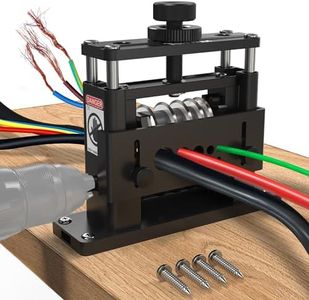

Manual vs. Automatic OperationWire stripping machines come in manual and automatic types. Manual machines require you to feed and turn the wire by hand, which is good for occasional use or small projects. Automatic (or powered) machines use electric or drill power to process wires faster and with less effort, which is ideal for large quantities or frequent use. Think about your workload: if you only strip a few wires now and then, a manual might suffice; for regular or high-volume work, an automatic machine will save you time and effort.

AdjustabilityAdjustability refers to how easily and precisely you can set the machine to different wire sizes or insulation types. It’s an important feature because wires vary, and being able to fine-tune the machine helps prevent damage to the wire. Simple machines have limited or basic adjustments, while more advanced models let you adjust cutting depth, feed guides, or blade positions. If you expect to use your machine for different types of wires and insulation, prioritize a machine with versatile and user-friendly adjustment options.

Construction and DurabilityThis specification covers the quality of the materials and how solidly the machine is built. Because wire stripping can put stress on parts, strong materials like steel housings and hardened cutting blades are signs of durability. Cheaper machines may use more plastic parts and may wear out faster. If you need a machine for heavy or frequent use, look for robust construction to ensure safety and long life. For only light duty, a lighter machine might suffice.

Safety FeaturesWire stripping machines can be potentially hazardous, so safety features are important. Look for shields around moving parts, safety switches, and mechanisms that prevent accidental blade exposure. Some machines include ergonomic handles or stable bases to keep everything steady. If user safety is a concern, or if less experienced people might use the machine, give preference to models with strong safety features.