We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

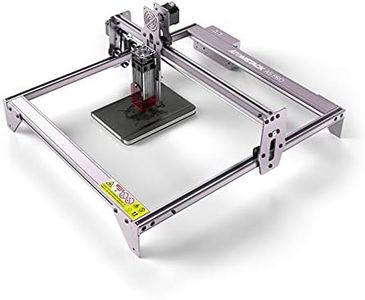

10 Best Engraving Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Engraving Machine

Choosing an engraving machine can feel overwhelming with all the technical jargon and choices on the market, but a good approach is to focus on what you need to engrave—like wood, metal, or plastic—and how often you plan to use the machine. Think about the size of your typical projects, the level of detail you want, and how easy the machine should be to operate. By narrowing in on these basics, you’ll be able to select an engraving machine that will suit your needs without being more complicated or powerful than necessary.Engraving AreaThe engraving area refers to the maximum size of the material the machine can work on at one time. This is important because it determines whether your projects will fit, or if you’ll have to split them into smaller pieces. Small engraving areas are good for jewelry, tags, or small crafts; medium areas allow more versatility for items like plaques or tools; large areas are best for big signs or large-scale projects. When choosing, think about the largest items you hope to engrave and select a machine that can accommodate them comfortably.

Laser Power (or Spindle Power)Laser power or spindle power measures how strong the machine is at cutting or engraving. Higher power allows deeper and faster engraving, and the ability to work on harder materials like metal or stone. Lower power is best for gentle engraving on soft materials like leather or plastic. Light-duty (low wattage) is fine for arts, crafts, or hobby use. Medium power can handle frequent use on wood, acrylic, and some metals. Heavy-duty power is best for business use or hard materials. Match the power to the material you’ll engrave most often, making sure you don’t choose more power than necessary for your projects.

Supported MaterialsSupported materials are the types of surfaces the engraving machine can work with, such as wood, metal, glass, plastic, or leather. Not all machines are designed to handle every type of material. Basic models might only engrave wood and plastic, while more advanced ones can handle metals or glass. Review what you want to engrave most often, and make sure the machine clearly lists those materials in its specifications.

Engraving Precision (Resolution)Engraving precision, sometimes called resolution, is typically measured in dots per inch (DPI) or millimeters. Higher precision means the machine can produce finer details and smoother curves, which is great for photographs or intricate patterns. Lower precision is sufficient for simple logos, text, or basic designs. If you need to create small, detailed artwork, opt for a machine with higher precision; for less detailed or larger designs, standard precision will suffice.

Ease of Use and Software CompatibilityEase of use covers how simple it is to operate the machine, including the kind of software you need for designing and sending projects to the engraver. Some machines come with beginner-friendly software, while others require knowledge of professional design programs. If you’re a novice, prioritize user-friendly interfaces and included software. If you have some experience or want more creative control, check compatibility with design programs you prefer to use.

Cooling and Safety FeaturesEngraving machines, especially lasers, produce heat and sometimes fumes. Cooling systems like fans or water cooling help prevent overheating, and safety features like emergency stops, enclosures, or fume extractors make operation safer. More basic machines have minimal protection, while advanced models include strong safety and health protections. Consider where you’ll use the machine (home, garage, workshop) and select appropriate safety and cooling features for peace of mind.