We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

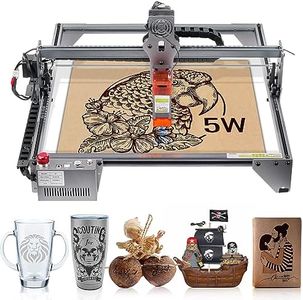

10 Best Wood Laser Engraving Machine

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Wood Laser Engraving Machine

Selecting a wood laser engraving machine can be exciting, as it opens up creative possibilities for crafting, gifting, or even small business projects. The key to finding the right fit is understanding what you want to make and how often you plan to use the machine. Think about the kinds of items you'll engrave, their sizes, and the level of detail you need. By knowing your needs, you’ll be able to focus on the most important features and pick a machine that’s easy to use, reliable, and matches what you want to achieve.Laser Power (Wattage)Laser power refers to how strong the machine's laser is and directly affects how deeply and quickly it can engrave or cut wood. A lower wattage (for example, around 5–20 watts) is usually enough for surface engraving and thin materials. Middle-range wattages (20–40 watts) allow faster engraving and cutting through somewhat thicker wood. High wattage (over 40 watts) is best for heavy-duty work and larger, deeper cutting tasks. Think about what types of wood you will use and whether you need only engraving, or also cutting, to pick the right power level.

Work Area (Engraving Size)The work area is the maximum surface the machine can engrave in a single run. Smaller work areas (such as 4x4 inches) are suitable for small crafts and personalized items. Medium sizes (like 12x8 inches) work well for larger signs or artwork, while large work areas (over 20x12 inches) are needed for big projects or batch processing. Consider the items you want to create or personalize—if you expect to work with larger materials, a bigger work area will be necessary. For hobby work or smaller crafts, a compact machine is often ample and saves space.

Engraving SpeedEngraving speed measures how fast the laser can move over the surface. Higher speeds mean quicker completion, which is useful for larger projects or commercial use. Typical ranges go from 100mm/s for basic machines up to 500mm/s or more for advanced equipment. If you need fast turnaround or plan to engrave many items, choose a higher speed. For personal use and occasional projects, slower speeds are usually sufficient and can even result in finer detail.

Supported MaterialsNot all wood laser engraving machines can handle the same types and thicknesses of materials. Some are designed exclusively for lighter woods, others can also engrave denser or thicker woods, as well as additional materials like acrylic or leather. If you plan to work on different types of wood or even other materials in the future, ensure the machine’s specifications include these. Matching the supported materials to what you’ll actually use saves frustration and possible machine damage.

Software CompatibilityThe machine’s software compatibility determines how easily you can create and send designs to the engraver. Some devices work with only specific proprietary software, while others are compatible with popular design programs or open-source options. Beginners may want easy, user-friendly interfaces with ready-made templates, while more advanced users might need flexibility and advanced features. Think about your comfort level and design needs—if you prefer drag-and-drop tools, look for machines with simpler software support; if you like custom designs or integration with drawing tools, wider compatibility is important.

Fume Extraction and Safety FeaturesLaser engraving produces smoke and particles, especially with wood, so a proper fume extraction or air filtration system is crucial for safety and clean indoor air. Some machines include built-in fans or exhaust ports, while others require an external system. Safety features may also include protective covers or emergency stop switches. If you’re working indoors or in a shared space, prioritize good fume management and safety mechanisms. For occasional outdoor use, these features can be less critical, but safety should always be a consideration.