We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

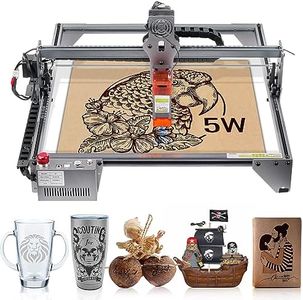

10 Best Metal Engraving Laser

From leading brands and best sellers available on the web.By clicking on a link to a third party's website, log data is shared with that third party.

Buying Guide for the Best Metal Engraving Laser

Choosing a metal-engraving laser can seem overwhelming, but understanding your specific needs is the best starting point. Are you working on jewelry, industrial parts, personalized gifts, or art? The kind of materials you’ll engrave, the precision required, and how much you plan to use your laser all play a big role. Consider the scale of your projects, how much detail you want, and where you’ll use the engraver (for example, a home workshop or a business setting).Laser TypeLaser engravers for metal commonly use two main types of lasers: fiber lasers and CO2 lasers. Fiber lasers are best for direct metal engraving, giving clean, precise results on bare metals and alloys; they’re more efficient and typically have a longer lifespan for metal work. CO2 lasers generally don’t engrave bare metal unless you use special coatings, so they’re more suited for coated metals or non-metal materials. Choosing between these depends on whether you’ll often engrave metals directly or want versatility for different materials.

Laser Power (Wattage)Laser power, measured in watts, determines what metals you can engrave and how quickly. Lower wattage (10-30 watts) lasers can handle simple markings, detailed designs, and thin metals but will be slower on tougher jobs. Mid-range power (30-60 watts) is good for everyday small business tasks, offering speed and flexibility. Higher power (60 watts and above) is meant for deep engravings, thicker materials, and faster production. Pick a power level by thinking about the thickness and hardness of metals you’ll commonly use and the speed you need.

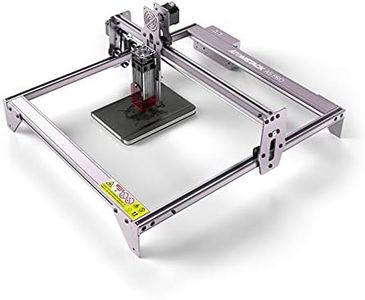

Working AreaThe working area is the size of the surface that the laser can engrave in one go. Small working areas (less than 8x8 inches) are fine for jewelry, tags, and small parts. Medium-sized areas (8x8 to 20x20 inches) give more flexibility for signs or larger items. Large working areas (over 20x20 inches) suit batch work or industrial applications. Choose a size based on the maximum dimensions of your regular projects, but remember that larger machines take up more space.

Precision and Minimum Line WidthPrecision reflects how accurately the laser follows your design, and minimum line width is the thinnest line it can produce. Higher precision (measured in microns or small fractions of a millimeter) is essential for fine details like tiny text, complex logos, or intricate artwork. Engraving industrial parts or making identification marks may not need extremely fine detail, so you can be less strict. Match this feature to your desired finished look and project complexity.

Supported MetalsNot all metal-engraving lasers work equally well with every metal. Some lasers are optimized for certain types (like stainless steel, aluminum, gold, copper, or titanium). Check the manufacturer’s information to see what metals a machine is rated for. If you mostly work with a single type of metal, make sure your engraver specializes in it. For general use or varied jobs, look for broad compatibility.

Cooling SystemLasers generate heat during use, so many have cooling systems—either air-cooled or water-cooled. Air-cooled systems are simple and quieter, suitable for small or medium jobs. Water-cooled systems are more efficient for higher-power lasers and frequent, long sessions, as they keep components from overheating. Choose the system based on your expected laser usage and workspace environment.

Software CompatibilityThe laser engraver uses software to control your designs and the engraving process. Some machines work only with specific software, while others support common design programs or file formats. Look for software that matches your skill level and workflow. If you want easy setup, look for user-friendly, plug-and-play systems. For advanced projects or custom automation, make sure it supports more complex design tools.